Optimization and improvement of the tilting mechanism of degassing equipment

Brief Description:

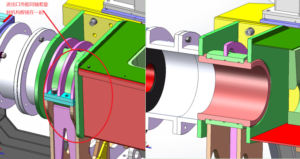

The original structure of the degassing and tipping device: the shaft sleeve is connected to the inlet and outlet channel shell plate by welding. When the lining of the circular tube flow channel in the shaft sleeve is damaged, the structure of the shaft sleeve cannot be disassembled separately and the round pipe must be replaced. It is inconvenient to line the pipe launder, as shown in the figure below:

The tilting mechanism of degassing equipment

Improvement methods:

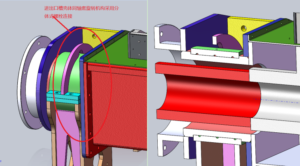

The improved structure of the degassing and tipping device: the shaft sleeve is connected with the inlet and outlet trough shell by bolts. When the lining of the circular pipe flow trough in the shaft sleeve is damaged, the structure where the shaft sleeve is located can be lifted out separately, and the damaged round pipe launder lining needs to be repaired and replaced. After repair, it can be quickly assembled into the tipping device, as shown in the following figure:

Field application:

Applied to 1525 Asia-Pacific double rotor tipping degassing equipment ( degassing unit):

1. After the lining of the round tube flow channel is damaged, the lining of the round tube flow channel can be installed separately in the shaft sleeve without having to replace the entire set of linings, which reduces costs.

2. Easy to install, reducing the labor intensity of workers and improving work efficiency.