Non-Sodium Granulated Flux is a white granular flux. It is prepared by mixing a variety of inorganic salts in a certain proportion after drying treatment. It is mainly used to remove hydrogen and floating oxidized slag inside the aluminum liquid.

Specifications

| Item | Internal Packagin | Carton Packaging | Pallet Packaging | Special Packaging | Storage & Guarantee |

| Index | 5kg/bag | 20kg/carton | 1.2T/pallet | As per requirement | Stored in ventilated and dry environment,6 to 12 months |

Effect

Non-Sodium Granulated Flux is mainly used to remove the hydrogen and floating oxidized slag inside the aluminum liquid, so that the aluminum liquid is more pure and has the function of a slag cleaning agent.

Working Principle

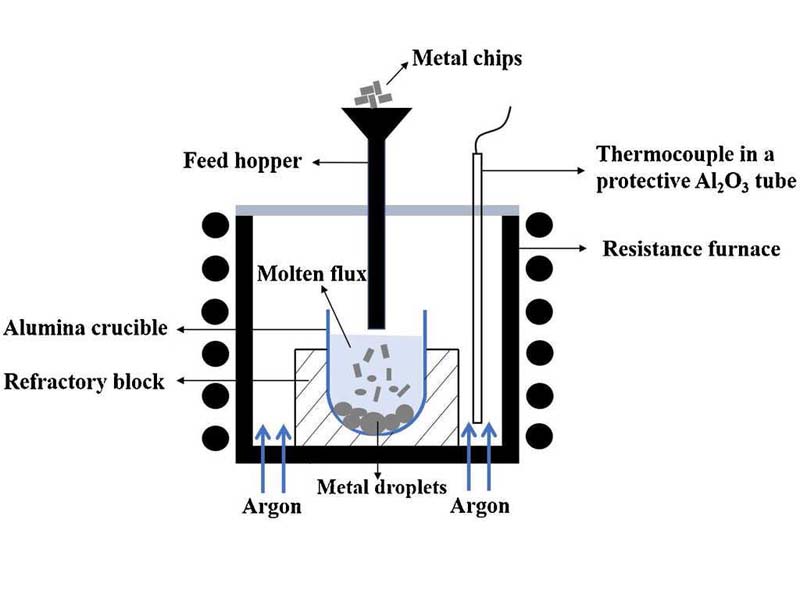

1. Through the jet machine under the action of carrier gas (N 2 or Ar) evenly enter the aluminum liquid, through physical and chemical changes in the aluminum liquid to form countless small bubbles in full contact with the aluminum liquid

2. Separation of [H] and other harmful gases in the aluminum liquid

3. At the same time, some substances contained in the refining agent can strongly adsorb and melt the oxides and suspended matters in the melt and adhere to the bubbles together.

4. With the rise of bubbles, it is brought to the surface of the aluminum liquid, so as to achieve the purpose of refining and purification such as gas removal and slag removal

Features

1. Some components in the refining agent are easily decomposed at high temperature, the generated gas is easy to react with hydrogen, and has strong adsorption force with the slag, and quickly escapes from the melt.

2. Has the function of slag cleaning agent.

3. Less smoke, reduce burning loss, environmental protection and economy.

4. The amount of refining agent per ton of aluminum is 1.5-2.0kg, and the amount of aluminum ash discharged is 0.8-1%, and it meets the requirements of high-precision aluminum alloy casting, which effectively improves the yield of molten metal 0.6-0.8% and achieves the purpose of energy saving and consumption reduction.

Range of Use

It is suitable for common aluminum alloys (alloys with high magnesium content and aluminum-magnesium alloys cannot be used), and pure aluminum smelting, degassing refining and slag removal.

Instructions

1. Sprinkle the refining agent on the liquid surface, quickly press it into the aluminum liquid, stir it well, let it stand, slag

2. It is better to use an inert gas to spray the refining agent into the aluminum liquid with the help of a spray machine.

Dosage

1. The general dosage is about 0.3% of the weight of the aluminum liquid

2. The details should depend on the purity of the molten aluminum.

Covering agent, slagging agent, slag cleaning agent, refining agent used in aluminum alloy melting

1. When the temperature of the aluminum alloy reaches about 660-720 degrees, add the refining agent. Press the tool to the bottom until no bubbling occurs. It is mainly used to remove hydrogen from the aluminum liquid. Refining agent: zinc chloride.

2. Add slagging agent after refining, remove the slag after fully stirring with tools, mainly used to remove impurities in the aluminum liquid, slagging agent is mainly used for lead alloy smelting.

3. After the slag is cleaned, spread covering agents such as expanded perlite and expanded graphite on the surface to prevent the hydrogen in the air from entering the aluminum liquid and keeping it warm.

4.After the melting of aluminum and aluminum alloys, the furnace cleaning agent cleans the furnace wall.

One-Stop Shopping for Aluminium Melting Materials