Degassing Unit has an ultra-long life furnace body using new high-silicon molten material manufacturing technology.

The degassing rotor, heater protection sleeve, and thermocouple protection sleeve are all made of silicon nitride (Si3N4) ceramic manufacturing technology.

Degassing Unit is installed between the furnace and the casting machine.

It is to exclude hydrogen and other residues contained in molten aluminum and its alloys that affect its quality and mechanical properties.

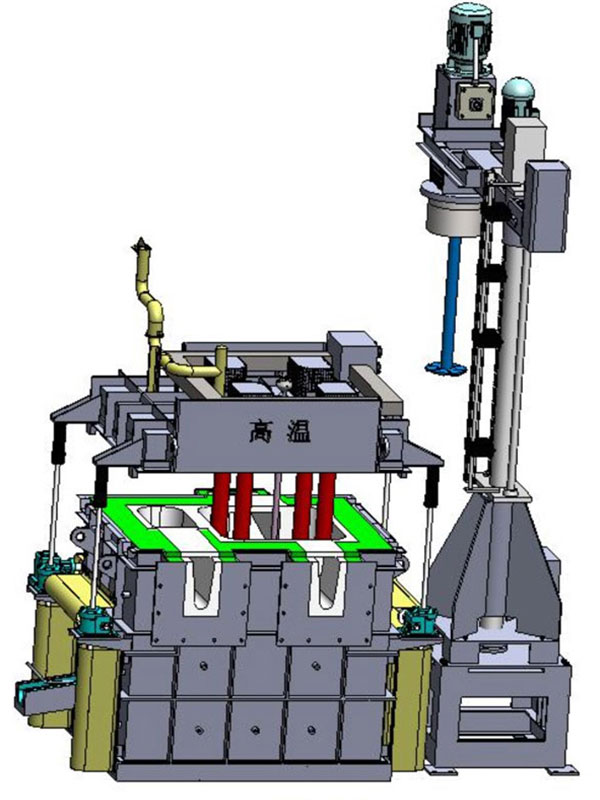

degassing unit

Aluminium Degassing Unit Including

Mechanical transmission

Box cover

Rotor and heater

Electrical control

Degassing-Methods-In-Casting

Parameters of Online Degassing unit:

| Max Degassing flow MT/H |

15 MT/H | 35 MT/H | 65 MT/H |

|---|---|---|---|

| Degassing Box Standard | 1 room 1 rotor (1B1R) | 2 rooms 2 rotors(2B2R) | 3 rooms 3 rotors(3B3R) |

| Degassing box structure | 1 draining outlet & 1 deslagging outlet | 2 draining outlets & 1 deslagging outlet | 3 draining outlets 1 deslagging outlet |

| Lifting System | Hoisting type | Rotor mechanical lifting | cover hydraulic lifting |

Equipment Performance

The Degassing Unit mainly processes molten aluminum liquid containing a certain amount of hydrogen and other residues (alkali metals, slag inclusions), which are eliminated after processing by degassing equipment.

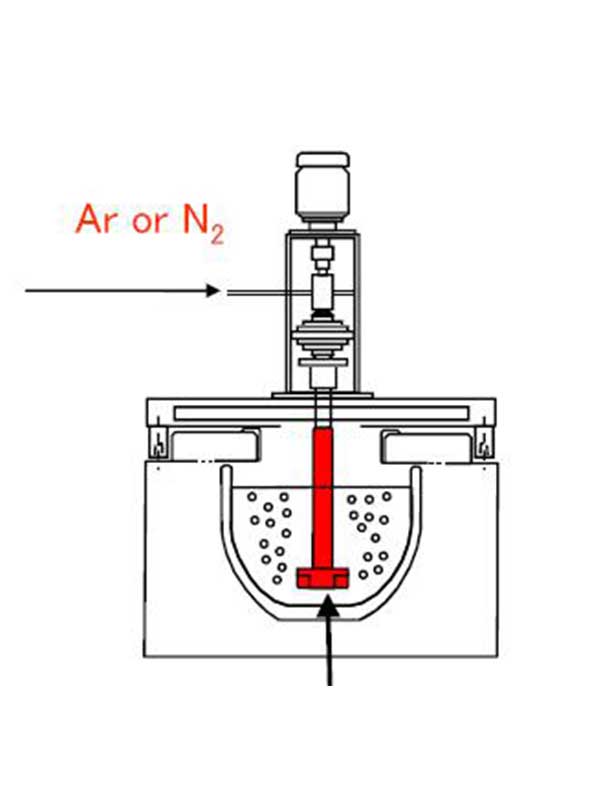

Working Principle

The process gas (inert gas or a mixture of inert gas and chlorine) is injected into the melt through the rotor and broken by the rotor into evenly dispersed tiny bubbles, which rise to the surface of the melt.

Complete the following work during the rise of tiny bubbles

1. Hydrogen is absorbed into the bubbles and is excluded.

2. Alkali metals are excluded by chemical action with chlorine gas (chloride formation).

3. The inclusions are captured by air bubbles and then rise to the surface of the melt to form dross.

| The design standards of degassing efficiency | The average Degassing efficiency is 60%. If use Ar and Mg content ≤1%, the efficiency can reach 0.09cc/100g. |

|---|---|

| The design standards of lining structure | The lining is made of high silicon molten material, average working life is 2-3 years. It is featured nonstick aluminum, with no contamination. There is a float stopper inside to prevent oxides from being drawn into molten aluminum and the bubbles or slags from running out. |

| The design standards of the rotor | It is made of SiN. Working life is 2-5 years. It performs well in corrosion resistance, heat shock resistance, oxidative resistance, abrasive resistance, and mechanical strength. Shaft diameter 60mm, head diameter 200mm, which shall reduce resistance in stirring. Speed design 450-550 R/M will crush bubbles and disperse evenly into aluminum. It is cost-effective during long-time usage. |

| Intrusive heater protection thimble | It is made from SiN, Average service life is 1-2years, featured high heating efficiency, oxidation and slagging prevention, and no contaminations. |

| The gas protection design | Ar mix of N2 and chlorine is available, protection method is also designed. |

| Sealing structure design | The sealing structure includes a cover, lining, inlet, and outlet to prevent slag and improve degassing efficiency. |

Operating Principle of Degassing Methods

The inner liner of Degassing Unit is integrally formed with high-silicon molten material, which has a good non-stick aluminum effect and long service life.

Degassing Unit Instructions for use:

1. When the oven is over, turn off the heating element before the molten aluminum melt enters the cabinet.

When the temperature of the heater and the temperature of the molten aluminum are close, an inert gas is introduced into the rotor, and then the molten aluminum liquid is filled into the tank.

2. Check the sealing material at the connection between the inlet and the outlet and the launder.

Check that the bottom drain with high-temperature protection is tightly plugged.

Check whether the temperature of the molten aluminum filling the tank is high enough (minimum temperature: 720 ° C). To observe the molten aluminum entering the tank, stop the filling operation at a level of approximately 3 cm from the bottom of the flow cell.

3. The lid of the box is closed (the box has a slag opening) The operator must wear an appropriate protective jacket.

When the metal flows into the box, a dross is generated, and the dross on the metal surface can be skimmed through the slag opening.

4. It is recommended to raise the temperature to above 780 degrees for re-production, start the temperature insulation stage, and close the slag opening.

5. The heat preservation stage allows the aluminum liquid in the casting time to be kept in the box at the temperature set by the operator,

No molten aluminum is processed during this insulation phase.

6. A small amount of inert gas needs to be introduced into the rotor to prevent aluminum liquid from entering the rotor and blocking the rotor air outlet.

After the filling operation of the molten metal is stopped, the heater needs to be started immediately, and the heating is controlled according to the metal heat preservation parameter, which is set by the operator.

7. By starting the heating system to control the temperature of the aluminum liquid, the gas flow rate needs to be monitored.

Switching from the speed in the holding phase to the speed set in the processing phase, the flow of inert gas into the rotor increases, from the flow in the holding phase to the flow in the processing phase.

The operator sets the temperature of the molten aluminum in the treatment stage and heats it in this mode to achieve a stable degassing working state.

One-Stop Shopping for Aluminium Melting Materials