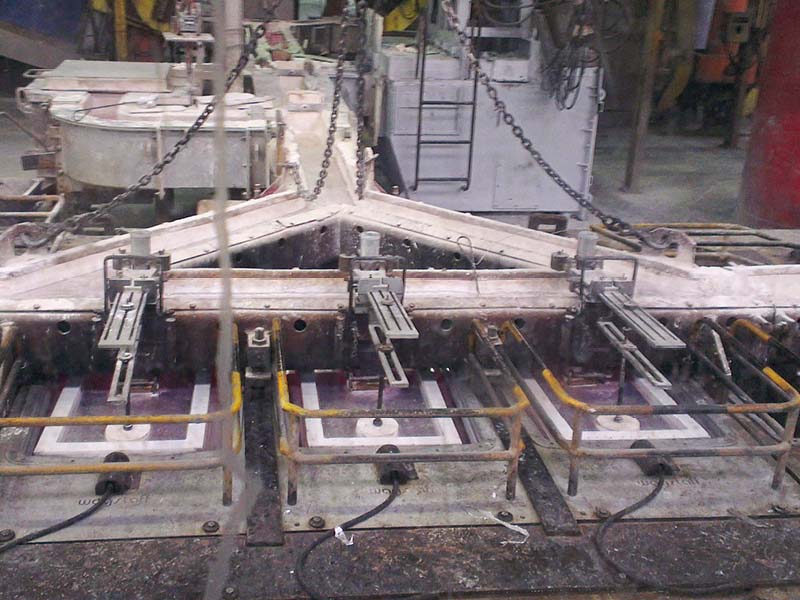

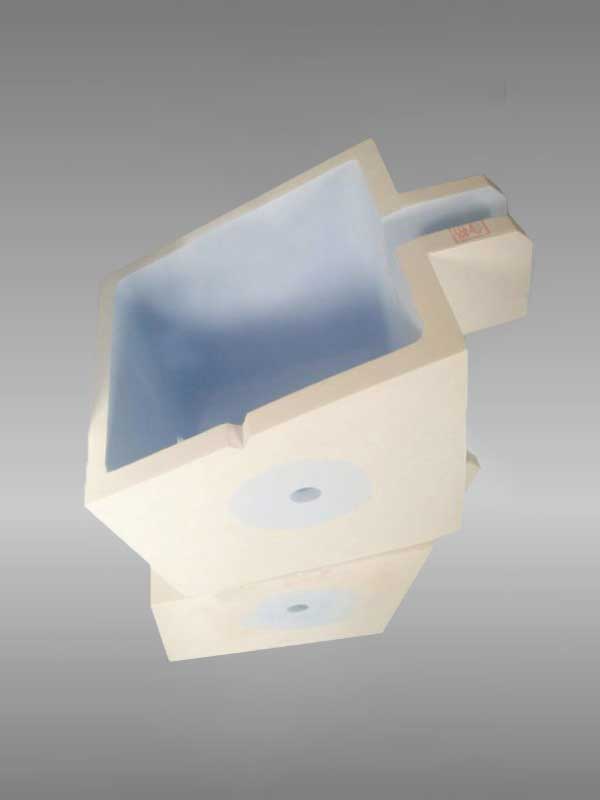

Tundish is assembled with Buoyage & Flow Duct and used to coordinate the flow rate of molten metal during casting and rolling.

Tundish is used between the split flow and flow channel of the matching casting nozzle plate, for the casting and rolling forming and size control of aluminum plates, aluminum strips and aluminum foils.

Adopt high-silicon molten material forming technology, corrosion resistance, non-stick aluminum, no slag.

In the process of liquid aluminum casting and rolling, the internal structure layer of the cast and rolled aluminum is protected to meet the product technology for the production of micro-level aluminum foil wool with high added value and high technical performance for casting and rolling, and PS plate base aluminum for printing.

Dimensions (mm)

| Item | Size | Flow Control Supporting | Customized |

| Standard | 200-600 | As Drawing | As Drawing |

Parameters

| Item | Density (g`cm3) |

Rupture modulus (816℃·Mpa) |

Thermal Expansivity (680℃·K-1) |

Thermal Conductivity (540℃w/m`k) |

Max Working Temperature(℃) |

|

| Typical value | Roll-PH | 1.0-1.4 | 10.5-11.8 | 1.23*10-6 | 0.5-0.65 | 1260 |

Instructions for Use

1. Corresponding to the drawing structure, install the flow control box to ensure that the inside is smooth and clean, without damage or cracks.

2. Evenly preheat the flow control box that has been installed, and heat up at a uniform speed for 1-2 hours.

Check that the surface of the lining is red, that is, within 800 ℃, to remove the adsorbed crystal water, close to the casting temperature, safe and efficient use.

3. The flow control box has no electric heating and baking conditions, so it has to be baked with flame.

The first key is to control the flame temperature, and the second is to prevent the flame from roasting directly and to avoid the thermal stress caused by local heating causing the liner to burst.