Caster Tip is used for crystal forming and size control of aluminum sheet and foil blanks in the casting and rolling production line.

Using nano-scale fiber composite material vacuum suction filter molding, processed and manufactured by high-precision equipment.

Dimensions (mm)

| Item | Length | Width | Thickness of tip | R radius | Shape |

| Value | 200-2300 | 50-600 | 1.6-10 | Constant value | Enterocoelia/Level |

Parameters

| Item | Density (g`cm3) |

Rupture modulus (816℃·Mpa) |

Thermal Expansivity (680℃·K-1) |

Thermal Conductivity (540℃w/m`k) |

Max Working Temperature(℃) |

|

| Typical value | Roll-PH | 0.45-0.57 | 42-48.8 | 1.35-1.56*10-6 | 0.12-0.15 | 1260 |

Instructions:

Caster Tip has uniform distribution of internal short fiber structure, moderate density, good thermal insulation, precise size, high oxidation resistance, no delamination and no block drop, low deformation, effectively protect the surface quality of cast and rolled coil, with boron nitride The effect of coating is better.

Caster tip is used in the casting and rolling process of multiple series of cast and rolled aluminum alloy products: micron-level aluminum foil wool, PS plate base for printing, elastic packaging materials, etc.

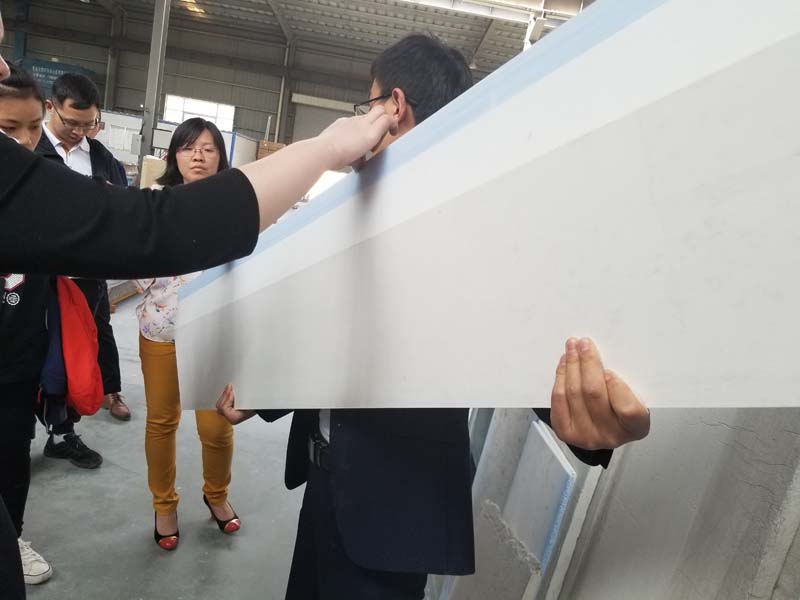

Caster Tip Structure

Nozzle plate

Gasket

Ears

Flow control box

Fixture

Runner

ProductAdvantages

1. High-precision equipment processing, small size tolerance.

2. The key parts are reinforced with nano-coating, which will not drop slag and resist aluminum liquid corrosion.

3. Symmetrical flow channel to meet the requirements of aluminum liquid hydrodynamics.

4. Effectively control the constant temperature of the casting and rolling area parameters.

5. Low deformation, easy to adjust the gap of the nozzle roller, improve the surface quality of the aluminum foil blank, and effectively improve the white stripes and dark lines.

Packing

An explosion occurs at the position of the Caster Tip, and the unsolidified aluminum liquid splashes, causing damage to the lip of the nozzle plate, slag hang, upturn of the oxide film, blockage of the internal cavity.

Analysis of the cause of the Caster Tip explosion

1.Caster Tip explosion refers to the phenomenon that the gas in the casting and rolling area or the casting nozzle instantly escapes from the aluminum liquid during the casting and rolling of the vertical plate.

2. There are two main forms of Caster Tip explosion, one explodes in the direction of the roll gap and the other explodes in the gap of the nozzle roll.

The explosion of the casting nozzle in the direction of the roll gap mainly occurs at the moment of the release of the vertical plate. The high-temperature aluminum liquid flows out of the feed pipe and contacts the nozzle plate and the wet roller surface with high water content. .

Breaking through the weak point of the aluminum liquid front near the inner cavity of the casting nozzle or the mouth of the casting lips instantly escapes, causing an explosion phenomenon.

3. The small bubbles in the aluminum liquid continue to gather in the casting area and the position of the lips, forming large bubbles with a certain pressure. There are two ways for the large bubbles to escape.

The first is that large bubbles break through the gap between the nozzle roll aluminum liquid, and the oxide film tension escapes from the nozzle roll gap, causing an explosion.

The second is that the internal pressure of the large bubble is greater than the adhesive force of the nozzle plate, so that the nozzle plate is damaged and escapes, causing an explosion.

From the analysis of the above reasons, it can be seen that the explosion of the casting nozzle is mainly caused by the evaporation of moisture and the accumulation of gas that cannot be discharged from the inner cavity of the casting nozzle and the casting area in time.

One-Stop Shopping for Aluminium Melting Materials – sales@adtechamm.com