The purpose of metal smelting is to smelt the chemical composition to meet the requirements and obtain the aluminum alloy melt with high purity, which creates favorable conditions for casting into ingots of various shapes.

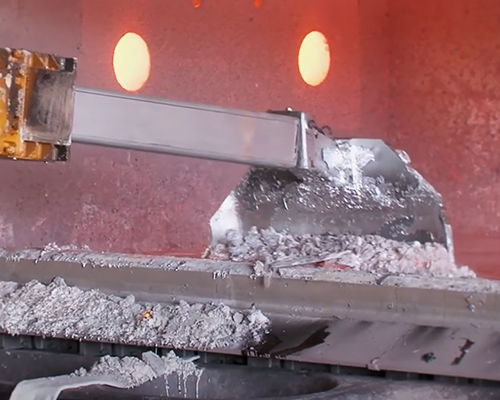

Aluminum is a very active metal. The chemical reactions that occur during the metal smelting process are irreversible. Once the metal is reacted, the metal cannot be reduced, which causes the loss of the metal. Moreover, the products (oxides, carbides, etc.) entering the melt will contaminate the metal and cause defects in the internal structure of the ingot. Therefore, in the smelting process of aluminum alloy, there is a strict selection of process equipment (such as furnace type, heating method, etc.), and strict selection and control of the process flow, such as shortening the smelting time and controlling the appropriate melting speed.

Metallurgical defects are particularly prone to occur during the smelting process, and are difficult to remedy in subsequent processing, and the metallurgical defects directly affect the performance of the material. Much of the occurrence of metallurgical defects are caused by the melting process, such as high gas content, non-metallic slag, coarse crystal grains, and primary crystals of metal compounds. Appropriate control of the chemical composition and impurity content and the addition of refining agents can improve the casting performance, and it is very important to improve the quality of the melt.

The basic requirements of the smelting process are to shorten the smelting time as much as possible, accurately control the chemical composition, minimize the smelting burning loss, use the best refining method and correctly control the smelting temperature, so as to obtain a smelting that meets the requirements of chemical composition and has high purity. body. The correctness of the smelting process is closely related to the quality of the ingot and the quality of subsequently processed materials.

For 2x×× series and 7××× series aluminum alloy pre-stretched plates in the smelting process, special attention should be paid to defects such as melt gas content, oxide film, metal compounds and inclusions.