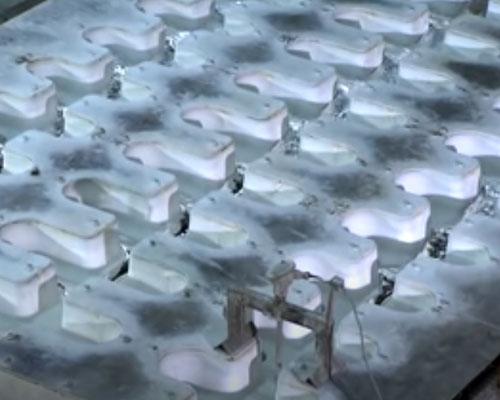

When casting with the new hot top casting equipment, the high temperature melt in the distributing launder directly rushes to the center of the liquid cavity of the ingot, thus forming a deep and sharp liquid cavity. There is a large tensile stress at the bottom of the liquid cavity, which is easy to cause the central crack.

In order to control the center crack, measures should be taken to avoid the liquid flow directly to the center of the liquid cavity and make it flow uniformly to the periphery of the ingot. At the same time, the melt temperature flowing to the periphery of ingot is increased, which is beneficial to prevent the central crack.

The temperature of the melt flowing to the periphery of the ingot is low, and there is a tendency to produce cold shut when casting large diameter ingots. The melt introduced from the draft tube into the mold flows to the periphery of the ingot

① The velocity of melt flowing to the periphery of the ingot is slow due to the obstruction of the lower surface of the guide pipe or casting transition plate.

② Affected by the heat conduction of the guide pipe and transition plate, the melt temperature flowing to the periphery of the ingot is low.

③ Under the influence of the minimum resistance rule, the high temperature melt from the distributing launder mainly rushes to the center of the liquid cavity, rarely to the edge of the ingot.

Therefore, when the new hot top casting equipment is used, there is a tendency to form cold shut defects around the ingot. When casting ingots with large diameter, it is usually necessary to reduce the casting speed to prevent the center crack of ingot. Because of the decrease of velocity and flow rate, it is easier to cause cold shut defects.

Gas and nonmetal slag inclusion defects are easy to be produced due to poor exhaust and slag discharge conditions in the casting process. The secondary pollution of the melt after degassing and slag removal is difficult to avoid when it flows through the gating system. Therefore, it is necessary to strengthen degassing and slag removing refining of melt, and avoid secondary pollution of gating system when using new hot top casting equipment.