Cast-Rolled Aluminum Strip Quality

The quality of cast-rolled aluminum strip is generally related to the processing accuracy, configuration, and quality of auxiliary materials of the equipment itself. It mainly depends on the grinding process of the cast roll, the size of the roll gap, the lubrication of the roll surface, the casting temperature (the temperature of the aluminum melt in the front box), the strength of water cooling, ...

Read More…

Read More…

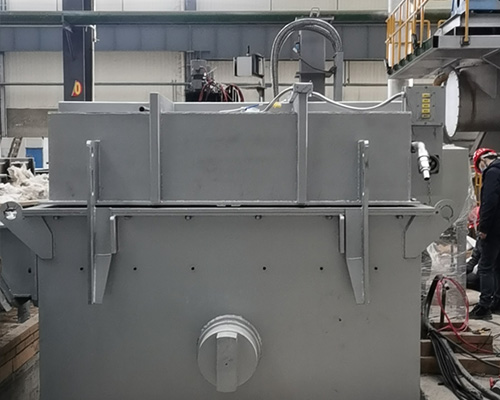

Deep Bed Devices

At present, the most widely used ceramic plate filter device, but its independent application in high-end products has greater limitations. Generally, ceramic plate filter devices need to be matched with other filter devices, such as deep bed or tubular filter devices. Tubular and deep-bed filtration devices are widely used in high-end aluminum processing products, and they occupy most of the indu ...

Read More…

Read More…

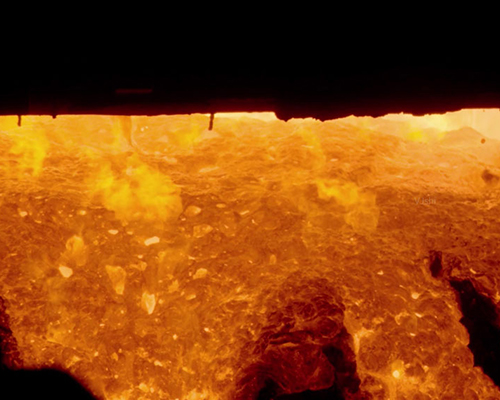

Online Degassing Purification

The purity of aluminum melt is one of the main factors that affect the pass rate of aluminum foil. The slag inclusions in the aluminum melt are not cleanly handled, which not only causes pores and embrittlement, but also accelerates the corrosion and causes the strip to break when the aluminum foil is rolled, causing excessive pinholes. In the production of cast-rolling double-zero foil blanks, on ...

Read More…

Read More…

Metal Melt Refining

Most of the casting and rolling manufacturers use high-purity argon or nitrogen as the carrier for refining, and purify the melt by blowing fluxes into the metal melt for refining. Because the inert gas is insoluble in aluminum, when the uniform and small inert gas bubbles are blown into the solution, the pressure of the hydrogen in the solution is greater than the pressure inside the bubbles, so ...

Read More…

Read More…

Double Zero Foil Production

With the improvement of aluminum foil quality requirements for aluminum foil downstream enterprises, aluminum foil manufacturers have higher and higher quality requirements for aluminum foil blanks. Based on the demand of various manufacturers to continuously reduce production costs, the use of cast-rolled materials to produce double zero foil has become the only choice for aluminum foil factories ...

Read More…

Read More…

Refining Molten Aluminum

How to improve the quality of the molten aluminum and effectively remove the inclusions such as hydrogen and aluminum oxide, the key is the refining process. Due to its non-toxic, odorless, light-shielding, moisture-proof, corrosion-resistant, light material, high barrier properties, UV resistance, easy to bend during deep processing and utilization, excellent adhesion and heat sealability, and go ...

Read More…

Read More…

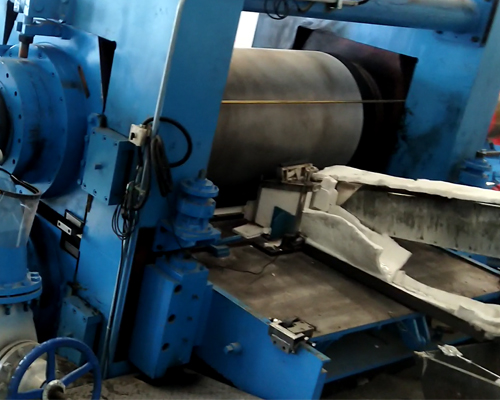

Cast Rolling Production

Cast-rolling production is widely used in aluminum alloy deep-processing production. The cast-rolling production has the advantages of short process flow, low energy consumption, small dendritic distance, and fine intermetallic compounds. However, in the actual production process, there are various defects in the broken cast-rolled plate, among which the cracked edge is a common defect in the prod ...

Read More…

Read More…

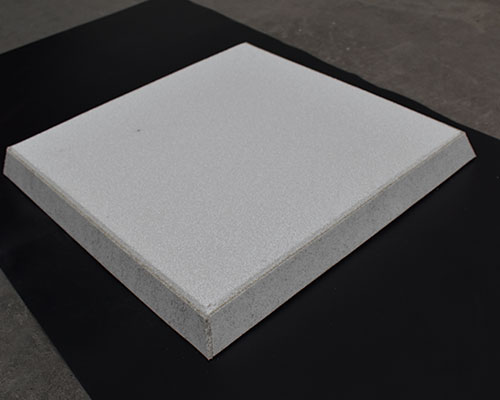

Ceramic Foam Filter Alma Aluminum

Ceramic Foam Filter Alma Aluminum is suitable for casting aluminum alloys such as aluminum rods, aluminum ingots, and aluminum plates. Since the ceramic foam filter is used to filter the metal oxides and other solid slag contained in the molten metal during the casting process, thereby improving the quality and yield of aluminum alloy, the use of the ceramic foam filter promotes the technology of ...

Read More…

Read More…

Ceramic Foam Filter Aluminerie Alouette

Ceramic Foam Filter Aluminerie Alouette is very important to the quality of aluminum melt, which greatly affects the subsequent processing performance and the quality of the final product. Foundries all over the world attach great importance to the purification of aluminum melt. There are many reasons for aluminum pollution. On the one hand, during the smelting process, aluminum is exposed to the ...

Read More…

Read More…

Ceramic Foam Filter Becancour Aluminum

Ceramic foam filter Becancour Aluminium is mainly used in metallurgy and foundry industries to filter impurities in molten aluminum, reduce pores, eliminate turbulence in metal flow, and improve casting quality. When the speed of molten aluminum flowing through the cast filter is too low, due to the collision probability of small inclusions, it is not easy to be adsorbed, but flows "smoothly" thro ...

Read More…

Read More…