In the past decades, the metallurgical industry has adopted refining measures to improve the quality of the melt. The so-called refining is to pass chlorine, inert gas or some chlorine salt into the melt to remove gas, inclusions and alkali metals from aluminum alloy. With the development of modern science and technology, there are many new methods of aluminum alloy melt purification. The content of these methods has exceeded the meaning of refining aluminum.

Therefore, the concept of melt purification has been introduced into modern science and technology. The so-called refining process of molten aluminum and refining gas in the furnace is to remove the harmful elements in the melting and refining process, including physical and chemical methods.

Flux Refining Aluminum

Fluxes consisting of salts containing chlorine and fluorine are used for degassing molten aluminum alloys. Degassing flux is usually formed in tablet form.

Degassing aluminum is initiated when the flux platen is immersed in the bottom of the furnace by a clean preheat piercing bell. The flux component reacts with aluminum to form gaseous compounds (aluminum chloride, aluminum fluoride). The gas bubbles and rises in the melt. The hydrogen partial pressure in the formed bubble is very low, so it diffuses from molten aluminum into the bubble. Bubbles escape from the melt and are then removed through the exhaust system. This process continues until the bubbling stops.

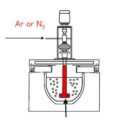

Online Degassing Unit

AdTech online degassing unit is mainly used for the hydrogen (H) and slags removal from molten aluminum. It takes gas flotation principles. The rotor takes inert gas or mixture of chlorine and inert gas into molten aluminum and smash the gas into dispersed tiny bubbles, the bubbles rise to molten aluminum surface and finish the below stated procedures at the same time.