The launder system for molten aluminum is an important part used in the aluminum and aluminum alloy casting process. It is usually installed between the melting furnace and the casting platform, and its main function is to guide the aluminum melt. The casting process of the secondary aluminum production system is to put the recycled […]

Tag Archives: Ceramic Fiber Launder

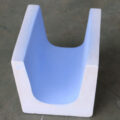

The lining material of the molten aluminum launder and trough is made of high-density molten silicon sintered, and the anti-aluminum infiltration material is added to improve the service life of the launder. At the same time, it has a small thermal expansion coefficient, better thermal shock resistance, and rapid cold and rapid heat resistance. Microporous […]

Launder for Casting is an important part of the aluminum casting process. After the molten aluminum in the holding furnace is processed in the furnace, it is transferred from the holding furnace to the online refining device, and then enters the casting machine through the launder for casting. Since the liquid level control accuracy is […]

The most technically advanced way to deliver molten aluminum from melting furnaces to holders and die casting machines is in a heated launder system. A launder minimizes turbulence and oxides in the molten metal. And, because the metal flows in a quiet stream to the holding furnace, it eliminates transfer labor and monorails, fork trucks, […]

Aluminum is guided into the casting machine from the melting furnace through the launder and storage tank. AdTech insulation launders have steel sleeves are lined with refractory materials, and they are open launders or launders with lids. The launder is suitable for installation at an inclination, and the melt flows through gravity. In order to […]

Contact Us

TEL: +86 371-87095601

E-mail: sales@alalloycasting.com

About Us

ADTECH is one pioneer following by the International Enterprise, who keeps focusing on the manufacture of the metallurgical material.

Address

NO.39 GARDEN ROAD, JINSHUI DISTRICT

ZHENGZHOU, HENAN, CHINA

TEL: +86 371-87095601

E-mail: sales@alalloycasting.com