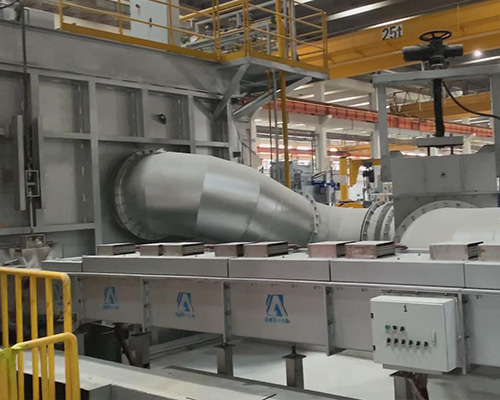

The launder system for molten aluminum is an important part used in the aluminum and aluminum alloy casting process. It is usually installed between the melting furnace and the casting platform, and its main function is to guide the aluminum melt.

The casting process of the secondary aluminum production system is to put the recycled scrap aluminum into the melting furnace to melt, and then the aluminum liquid flows from the melting furnace into the standing furnace for refining treatments such as degassing, slag removal, and standing, and finally standing the aluminum in the furnace The liquid is transported to the aluminum ingot casting machine through the launder for casting.

The launder system for molten aluminum installed between the smelting furnace and the casting platform is wrapped in a metal shell, and lined with thick aluminum silicate fiber paper, so as to ensure that the launder does not directly contact the iron shell and cause damage, and at the same time, it has a good thermal insulation effect.

During the installation of the launder, the molten aluminum flows with a suitable inclination through the action of gravity. The molten aluminum flows directly from the furnace eye of the smelting furnace, is transported to the casting machine platform through the casting launder, and then diverted to the splitter plate through the upper launder of the casting machine, flows to the crystallizer, and finally cools and crystallizes into an aluminum casting rod product. The launder installed on the casting platform does not require a metal shell.

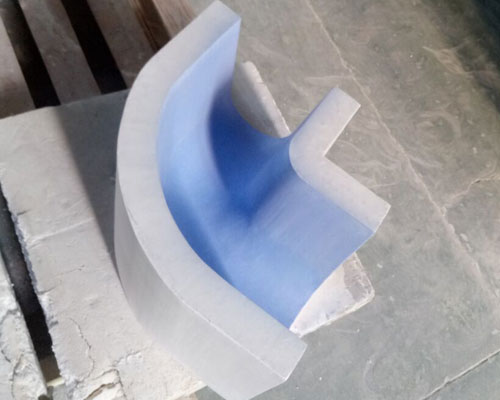

According to different structures, the launder and trough can be divided into direct flow trough, oblique flow trough, branch flow trough, corner flow trough and lifting flow trough, etc. Flow troughs of different structures use different parts and have different functions. Launder and trough can be divided according to different materials There are two categories of ceramic launders and cast material launders. Among them, ceramic launders have the advantages of good insulation performance, low density, and high specific strength, while cast material launders have the advantages of high strength, erosion resistance, and long service life. The launders of different materials are used in environments with different usage requirements.