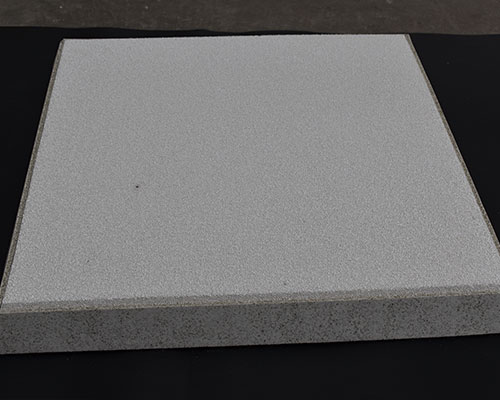

Ceramic foam filter is a commonly used filter tool in aluminum and non-ferrous alloy smelting industry. The foam filter is made of whiter high-purity alumina (Al2O3).

The alumina ceramic foam filter provides deep filtration to remove a large amount of impurities in molten aluminum, and the mesh filter provides thorough deep filtration to remove impurities in molten aluminum.

It has excellent resistance to high thermal shock, while maintaining continuous and thorough filtration to effectively remove impurities. The pore size is uniform, the porosity is high, the sintering is correct, the compressive strength is high, and the filtering effect is good.

Experiments show that when the pore size decreases, when the grade increases, the filtration efficiency will increase. For a given inclusion, the measured filtration efficiency (the width of the size interval is usually 5 to 10 um), usually for larger inclusions, the filtration efficiency is higher. However, when the inclusion size is about 50 um, the filtration efficiency will be reduced.

This trend is attributed to the capture, accumulation and subsequent release of inclusions in ceramic foam filter CFF.

Experiments have also determined that the increase in filtration speed will reduce filtration efficiency, and some brutal changes in filtration speed will cause the release of inclusions.

It has been applied to the deep filtration of liquid metal, especially the filtration of liquid aluminum through CFF. It has been found that the filter coefficients are dependent on the filter.

The deep filtering mechanism generally proposed by CFF:

The inclusions in the ceramic foam window at the top of the filter also accumulate and subsequently form a bridge. When the filter is good (grade greater than 50 ppi) and no grain refiner is added, the number of bridges is greater. The existence of this kind of bridge in the waste filter is related to a higher filtration efficiency value. The bridge caused a kind of filter cake filtration. For current industrial filtration conditions (the inclusion content is less than 1 ppm and the filtration speed is less than 20 mm, this filter cake filtration will not cause premature filter clogging (which will be encountered when the content of inclusions in the melt is high).