Ceramic Foam Filter For Metal Filtration is specially developed by AdTech for purifying molten aluminum. The molten aluminum flows through the tortuous and porous three-dimensional foam structure, and the tiny impurities are trapped, adsorbed, deposited, and firmly adhered to the pore walls, filtering out the micron-level impurities in the molten aluminum, and solving the aluminum alloy’s sensitivity to internal defects.

Ceramic foam filters suit different kinds of metallurgical applications. The reticular shape of the foam filter provides a thorough and deep filtration to remove impurities in the molten metal stream. Our ceramic foam filter uses good portiforium foam and high purity ceramic as raw material, can remove the non-metal solid mixture from aluminum and aluminum alloy fusant effectively in your aluminum casting industry.

The main way to remove slag by filtration is to purify the melt by the blocking effect of the filter medium, friction force, or fluid pressure to make impurities settle or block up. The production line adopts CFF two-stage foam ceramic filter plate, and the filter box is equipped with 2 sets of parallel filter plates. The filter board is a double-layer 30/50ppi composite foam ceramic filter board. The porosity of the upper filter plate is 30ppi, and the porosity of the bottom filter plate is 50ppi. The CFF foam ceramic filter can effectively remove slag inclusions with diameters greater than 20um, and the filtration efficiency can reach 75%.

Ceramic Foam Filter For Metal Filtration Dimension

660x660x50(26 inch)

584x584x50(23 inch)

508x508x50(20 inch)

432x432x50(17 inch)

381x381x50(15 inch)

305x305x50(12 inch)

228x228x50(9 inch)

178x178x50(7 inch)

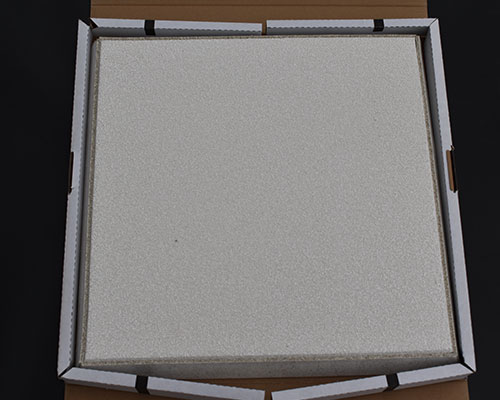

Ceramic foam filter Pore Size (PPI): 10/20/30/40/50/60

30ppi 40ppi Foundry Filter is the most commonly used ceramic foam filter in the aluminum casting industry.

Ordinary aluminum casting usually uses 10-40ppi ceramic filter plates.

Aviation and high-quality aluminum materials usually use 30-60ppi ceramic filter plates.

Aperture selection

1. The casting: 10~25ppi

2. Semi-continuous casting: 30~60ppi

3. High-quality aluminum or sheet: 50~60ppi

4. Continuous casting and rolling: 50~60p