Foam ceramic filter for aluminum casting filtration is very important for the quality control of aluminum. It can remove primary and secondary liquid/solid non-metallic inclusions in the metal melt, simplify the casting system, prevent inclusion defects, improve the mechanical properties of the casting, reduce the machining allowance of the casting, improve the surface finish of the casting, and extend the life of the machining tool.

Regarding the research on the mechanism of metal filtration and purification, there are mainly the following viewpoints, deep bed filtration mechanism, floating separation mechanism, adsorption mechanism.

Inside the foam ceramic filter, the path through which the melt flows is meandering.

It can greatly increase the probability of inclusion particles in contact with the filter. The flow rate and flow direction of the melt are changed faster, so that the fine inclusions in the melt are trapped and left behind at a certain point to be arrested.

Deep-bed filter and ceramic filter are widely used in molten aluminum filtration. A mathematical model that describes the filtration of liquid aluminum is proposed and experimentally verified.

Deep-bed filters consisting of tabular Al2O3 particles (where the bed height and Al2O3 particle size was varied) and ceramic open-pore filters were used to remove TiB2 “synthetic inclusions” from the melt. Inclusion capture kinetics for these two types of filters have been evaluated and quantified in terms of a kinetic parameter Ko. The results show that during filtration the open-pore ceramic filter behaves similar to a deep bed filter. However, as filtration proceeds, a cake filtration mode becomes prevalent. In both types of filters, filtration efficiency is shown to be strongly dependent on the melt approach velocity.

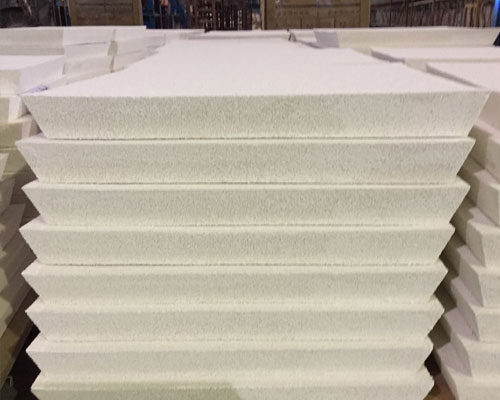

Foam ceramic filter for aluminum casting can reduce the casting spiracles, reduce the veins flowing when pouring the casting, reduce surface defects, obviously to improve the final-product rate.

The size are available in square, and custom geometric shapes. Sizes ranging from 10mm up to 600mm, and thicknesses from 10-50mm. The most common porosities are 10ppi, 20ppi, 30ppi, 40ppi, 50ppi, 60ppi. Higher porosities are available upon request. Custom-made cut-to-size filters are also possible.