The ceramic foam filter for aluminum foundry can remove the inclusions, make the metal more fluid, make the mold filling easier, the casting structure is better, and the thin section castability is better.

Removal of inclusions and other non-metallic debris from the melt will reduce mold welding and mold-metal interaction, thereby shortening mold surface and service life.

Oxide and intermetallic inclusions can form “hard spots” that can damage the tool during processing and finishing. Filtration reduces tool wear and improves productivity.

Inclusions may form holes and cause hot tearing during the curing process, leading to surface defects, impaired appearance and often reduced mechanical properties. In many cases, for these reasons, filtering can reduce waste to almost zero.

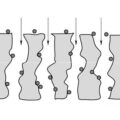

The filtration mechanism of the ceramic foam filter is a combination of adsorption, surface filtration and deep filtration. In terms of filtration and separation, it is stronger than liquid-solid and gas-solid systems. The filtration mechanism is mainly inertial collision, diffusion and interception.

Inertial collision: Due to inertia, the impurity particles in the fluid flowing through the microporous channel of the porous ceramic filter element are captured by contacting the wall of the microporous channel. The inertial collision is proportional to the square of the diameter of the impurity particles and inversely proportional to the flow velocity and fluid viscosity.

Diffusion: The impurity particles leave the streamline due to Brownian motion and contact the wall of the microporous channel to be captured. Diffusion capture is inversely proportional to flow rate and fluid viscosity.

Interception: Impurity particles are captured because they are larger than the pores of the micropores that act as surface filters. The retention rate is only related to the size of the impurity particles, and has nothing to do with the flow rate and fluid viscosity.

When the fluid flows through the ceramic foam filter for aluminum foundry, particles larger than the pore size of the filter element are captured on the surface, forming a filter cake layer. Some particles are trapped on the surface or deposited in porous ceramic channels.