Corundum tube filter, ceramic foam filter, and deep bed filter have three different filtration methods. Although the structure is the same, the interception and capture mechanism of impurity particles is basically the same.

No matter what kind of filter, the size of the particles that can filter out impurities is much smaller than the size of the pore size of the filter medium. The reason is that the quality particles are captured by the filter medium. There are mainly four situations as follows:

- Direct interception: When the size of impurity particles is larger than the pore size of the filter medium, they are blocked out of the pores and filtered out.

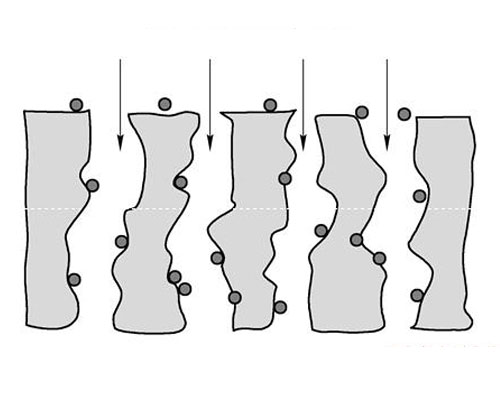

- The inertial force causes the impurity particles to deviate from the flow direction of the fluid, and are attracted by the thin wall of the filter medium pores and are retained.

- The impurity particles make irregular Brownian motion in the melt, and when they collide with the filter medium, they are adsorbed by the medium and stayed.

- Impurity particles are deposited on the wall of the filter medium due to gravity and are captured.

No matter what filtration methods are used, the filtering effect is related to the flow rate of the molten metal. The lower the filtering speed, the better the filtering effect, and vice versa.

The comparison of different filtration methods is as follows: The advantages of deep-bed filters are thick filtration layer, long flow path, and more adsorbed impurity particles. The flow rate is large, up to 5100t/h, suitable for large-scale and mass production. However, deep bed filtration only uses filling to form a filter layer, and the filter medium is easy to loosen and move, causing some small impurities to be stirred into the melt and reduce the filtering effect.

The filter tube of the tubular filter adopts a fixed structure, and the structural particles of the filter tube itself do not move loosely like the filter layer of the deep bed, so the filtering effect is good. However, the initial pressure of the filtration is large, the replacement of the filter tube is troublesome, and the filtration cost is high.

Compared with the corundum tube, the ceramic foam filter has a larger pore diameter, a smaller density and a lower filtration accuracy. Compared with the deep-bed filter, the filter layer is thin, and there are fewer impurities and particles that can be adsorbed. But this can be improved by increasing the number of filtration stages, that is, two-stage and three-stage filtration can be used to improve filtration accuracy. Its advantages are small initial pressure head, convenient replacement, simple operation and better filtering effect.