The purification method in which the melt passes through a filter made of neutral or active materials to separate the solid inclusions suspended in the melt is called filtration. The filtration method is the most effective and reliable method to remove non-metallic inclusions in aluminum melt. According to the filtering properties, the filtering method of aluminum alloy melt can be divided into two types: surface filtering and deep filtering; according to the filtering material, it can be divided into mesh material filter cloth, metal mesh, etc.), block material filtering (such as loose particle packed bed, Ceramic filter, foam ceramic filter) and liquid layer filtration (such as flux layer filtration, electric flux refining) three categories. Among them, the simplest filtration method is the glass cloth filter, the better is the foam ceramic filter plate, filter tube, deep bed filter and so on.

Glass cloth filtering aluminum melt has been widely used in the world, and is generally used in the transfer process and melt filtering in the mold. This method is characterized by strong adaptability, simple operation and low cost, but the filtering effect is unstable. It can only intercept and remove large-sized inclusions, and is almost ineffective for small inclusions, so it is suitable for the production of ingots with low requirements, and glass cloth can only be used once.

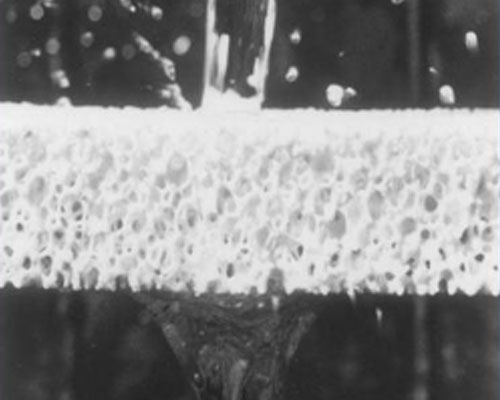

The foam ceramic filter plate is made by injecting a mixture of alumina and phosphate into the sponge plastic, and then drying and volatilizing the sponge plastic. It can also be called a microporous mesh foam ceramic sheet with a sponge-like structure. The aluminum melt flows along the tortuous channels and pores when passing through the filter plate, and the inclusions in it are in contact with the inner surface of the filter material pore under the action of deposition, inertia, flow force, interception, etc., and stay on the inner surface of the pore and the gap. The inclusions are left in the filter material and separated from the aluminum liquid.

Foam ceramic filter plate is easy to use, good filtering effect, low price, and it is widely used all over the world. The molten metal is filtered with foam ceramic filter plates. The foam ceramic filter plate is generally 50mm thick, 200~600mm long and wide, and its porosity is as high as 8%. It does not require a high pressure head when filtering, the initial size is 100-150mm, and later only 2-10mm.