What is Porous Ceramic Filtration?

A porous ceramic filter is a kind of ceramic filter material made of refractory raw material as aggregate, combined with binder and other high-temperature sintering. Its structure has a large number of fine pores with controllable pore diameter. In addition to its high-temperature resistance, high-pressure resistance, acid resistance, alkali corrosion resistance, etc., it also has the characteristics of uniform pore size and high permeability. So porous ceramic can widely be used as filtration, separation, gas distribution, and noise reduction materials. At present, with its unique functional characteristics, ceramic foam filters have become an irreplaceable product in the field of separation and purification.

Performance of Porous Ceramic Filter Material

There are various types of porous ceramic materials and specifications. Among them, the materials of porous ceramics are mainly aluminum silicate, clay, corundum, quartz, silicon carbide, and diatomaceous earth. The material performance of porous ceramic filter elements mainly includes the following aspects:

- Aperture: the size of the pores of the product opening, here, it refers to the maximum opening diameter of the product. The pore size of porous ceramic filter elements can be divided into 1, 5, 10, 20, 30, 50, 80, 100, 120, 150, 200, 250, 300Lm series.

- Porosity: The volume of the open pores in the product as a percentage of the total volume V opening / V total.

Permeability K: the dry gas amount (m 3) of a porous ceramic with a thickness of 1 cm and an area of 1 m 2 in a unit time of 1 h under a pressure difference of 1 mm H2O. - Acid resistance: The ratio of the bending strength of porous ceramic products to the bending strength before corrosion after being boiled in 20% sulfuric acid solution for 1h.

- Alkali resistance: After the porous ceramic product is cooked in 20% N NaOH solution for 1 hour, its bending degree and the bending strength percentage before corrosion are calculated.

- Temperature resistance: The ability of porous ceramic products to resist temperature changes without damage.

Characteristics of Porous Ceramic Filter Material

Compared with other filter materials, porous ceramics have the following characteristics as filter materials.

- Porous ceramic filter material has high porosity, up to 60%. The pore size is uniform and easy to control. High filtration accuracy, up to 011Lm, suitable for precision filtration of various media.

- Good acid and alkali resistance. It can be used to filter strong acids (sulfuric acid, nitric acid, hydrochloric acid), strong bases (sodium hydrochloride, etc.), and various organic solvents.

- High mechanical strength, working pressure up to 6M Pa, differential pressure up to 1M Pa.

- High-temperature resistance, good quenching, and quenching performance, working temperature up to 800 ℃. Suitable for all kinds of high-temperature gas filtration.

- The filter element is clean, non-toxic, odorless, and free of foreign matter. It is suitable for aseptic processing operations.

- The filter element has a long service life, and long-term use, and the pore shape does not change, which is convenient for cleaning and regeneration.

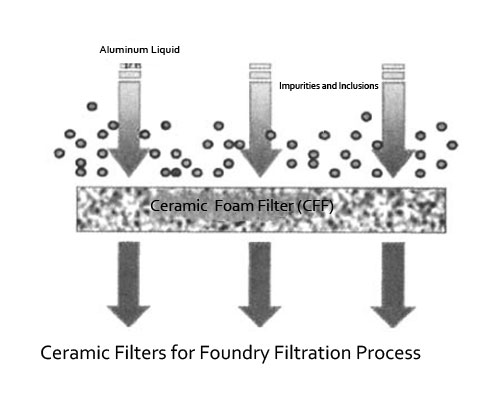

Porous Ceramic Filtration Principle

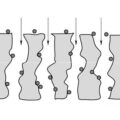

Porous ceramic filtration is a combination of adsorption, surface filtration, and deep filtration. In terms of filtration and separation, which are firmer than liquid-solid and gas-solid systems, the filtering mechanism is mainly inertial collision, diffusion, and interception.

Inertial collision: Impurity particles in the fluid flowing through the micropore channels of the porous ceramic filter element are captured by contact with the walls of the micropore channels due to inertia. Inertial collision is proportional to the square of the diameter of the impurity particles, and inversely proportional to the flow velocity and fluid viscosity.

Diffusion: Impurity particles leave the streamline due to Brownian motion and come into contact with the walls of the micropore channels, thereby being captured. Diffusion capture is inversely proportional to flow rate and fluid viscosity.

Interception: Impurity particles are captured because they are larger than the pores of the micropores, which is a surface filter. Retention is only related to the size of the impurity particles, but not to the flow rate and fluid viscosity.

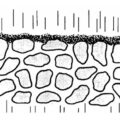

When the fluid flows through the porous ceramic filter element, the particles larger than the pore size of the filter element are trapped on the surface to form a filter cake layer. Some particles are trapped on the surface or deposited in porous ceramic channels.