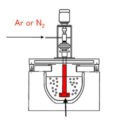

Inert gas rotary injection was first applied to continuous aluminum liquid refining in large melting furnaces. Each rotating nozzle is composed of a graphite rotating rod and graphite blades, and the inert gas is passed into the liquid through a specially designed rotating rod and blades. The rotation of the nozzle and the shearing action of the blades make the inert gas bubbles uniformly dispersed in all parts of the crucible liquid, and at the same time, a vortex is formed in the depth of the liquid and rises slowly, so that the bubble and the liquid have the largest contact area, which is effective Removal of hydrogen and slag created favorable conditions.

In addition, the inert gas does not react chemically with the molten aluminum, and there is no passivation film on the surface of the bubbles, which can easily adsorb hydrogen and oxidized slag, and float to the liquid surface by the buoyancy of the bubbles. The gas is sheared by the rotating blades, the bubbles are distributed extremely uniformly in the melt, and the melt is agitated, which expands the range of action interface, prolongs the action time, and increases the concentration gradient of hydrogen diffusion and mass transfer into the bubble, thus strengthening The role of hydrogen removal and slag removal. Strong stirring also promotes the accumulation of small slag inclusions, which is beneficial to the removal of floatation. The liquid surface of the alloy only rotates steadily without strong tumbling, so there is less slag formation and less air suction.

In the development process of aluminum liquid refining purification, the powdered refining agent and inert gas are sprayed into the bottom of the crucible together. Through a series of physical and chemical effects, the purpose of degassing and slag removal is achieved. The gas and slag inclusion in the aluminum liquid are obviously reduced, and the hydrogen and slag removal effect is remarkable. While rotating and blowing, the rotating blades of the nozzle are shearing the gas, so that the refining agent is evenly dispersed in all parts, so that the refining agent reacts with the gas in the aluminum liquid more fully, and the action time is prolonged, which is more conducive to removing the gas and Inclusions.