Ceramic foam filters for foundry can improve the filtration efficiency of particles from liquid metal. The filter also has the ability to capture small particles in the metal, which may become defects in the casting. The filter reduces the cost of casting manufacturing. Metal castings are made by pouring molten metal through a gate system […]

Generally, the continuous casting process of molten aluminum is carried out on a commercial scale. The continuous caster process usually includes a pair of rotating water-cooled continuous caster rolls, in which the molten metal enters the rotating continuous caster roll through a feed caster tip and nozzle just before the production line closest to the […]

Molten metal flux can remove dissolved and suspended impurities, including oxides, nitrides, carbides, and carbonates of molten metals and alloying elements. Dissolved impurities include dissolved gases and dissolved solids. The dissolved gas in molten aluminum includes, for example, hydrogen, and the dissolved solid particles include alkali metal elements such as sodium and calcium. For example, […]

The molten aluminum CFF filter is placed in the filter box, and the filter is arranged at a position upstream of the mold to remove alloy inclusions in the molten aluminum. The molten aluminum CFF filter includes a gathering mesh member made of a refractory material and a coating layer formed on the surface of […]

The feed casting tip is a key component of the aluminum strip continuous casting and rolling mill, and its quality directly affects the quality and output of the aluminum strip. It includes a narrow inlet at the rear and a wide inlet at the front. In the material passage between the inlet and the discharge […]

Ceramic foam filters are used to remove or reduce entrained solids from the final cast product, especially for molten aluminium, especially when the resulting metal is used in decorative products, for example as a decorative border made of 5000 series aluminum alloy Strips or plates, such as 5252 and 5657 aluminum alloys. Other aluminum alloys […]

Boron nitride is usually applied to the filter in the form of a water-based slurry. The particle size of boron nitride is preferably at least 1 micrometer to no more than 15 micrometers. Above about 15 microns, platelets can span surface undulations or pores, thereby reducing effective porosity. The preferred particle size is about 5 […]

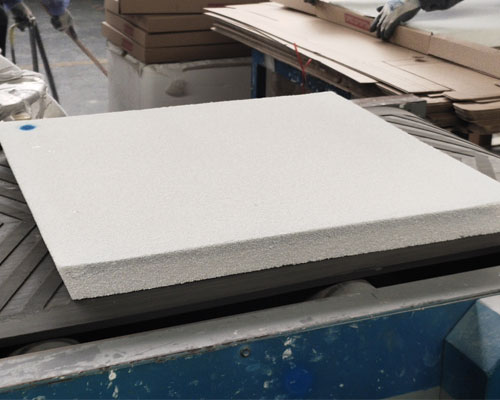

The initial foam ceramic filters manufacturing is formed by coating the reticulated polyurethane precursor with a ceramic slurry. The reticulated open-cell foam, preferably polyurethane foam, is impregnated with the ceramic slurry, wherein the entire structure of the reticulated open-cell foam is preferably covered by the slurry. The pore size of the foam is preferably between […]

Commercial aluminum-lithium (Al-Li) alloys are mainly used in aerospace applications due to their low density, high specific modulus, excellent low-temperature toughness, and excellent fatigue crack growth resistance. Every time 1% by weight of lithium is added, the density of the AL-Li alloy can be reduced by about 3%, and its stiffness can be increased by […]

Most of the structure of the caster tip body is made of ceramic material. However, the caster tip body may also include some other materials, including for example some higher thermal conductivity materials that are designed to enhance heat transfer through the caster tip body. Because ceramic materials generally have relatively low thermal conductivity, when […]