The ceramic filters for foundry use filtration technology to reduce impurities and inclusions in the molten aluminum before casting. The quality of the liquid aluminum treatment will affect the product quality of the ingot, which in turn affects the product quality of the subsequent processed materials. Therefore, the ceramic filter for foundry technology is an important part of the aluminum processing technology. And AdTech ceramic foam filter is an important application of this technology. It is widely used in aluminum foundries.

Ceramic Filters for Foundry

The foam ceramic filter (CFF) box is composed of multiple layers of refractory materials and steel. The refractory material in contact with the melt adopts a non-stick aluminum castable. Some filter boxes are also equipped with a heating device, which is arranged on the top or bottom, so as to play the role of thermal insulation melt.

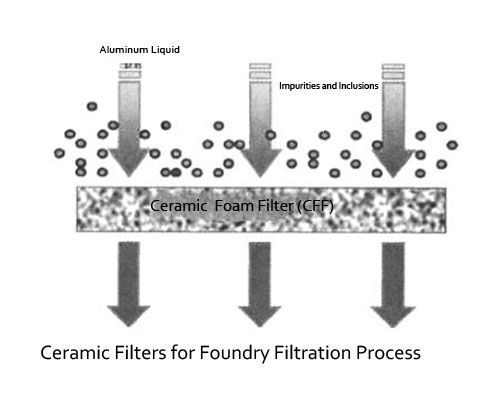

During filtration, the aluminum liquid is blocked by the CFF plate, and flows along the tortuous channels and pores in the ceramic foam filter plate. Impurities and inclusions in the aluminum liquid are firmly retained in the filter plate and separated from the aluminum liquid.

In the figure, the arrow indicates the flow direction of the aluminum melt, the upper part of the ceramic foam filter plate is the unfiltered aluminum melt, the lower part is the filtered melt, and the small balls indicate the impurities and inclusions in the melt. When the melt flows through the filter plate, impurities and inclusions are filtered out.

The service life of a single filter plate depends on the size, the number of holes and the cleanliness of the metal. In order to improve the filtration effect, some aluminum foundries have considered two-stage filtration. It has a better filtration effect. If you are interested in our ceramic foam filter, please feel free to contact us.