The ceramic foam material is made by impregnating an aqueous slurry on the struts of a flexible open-cell polymer foam precursor. The subsequent drying and firing of the material produces the final ceramic foam filter product.

The foam precursor may be any type of material that has sufficient resilience to restore its original shape after compression. Generally, polyurethane foam is used for this purpose.

The ceramic slurry is prepared by mixing the required ingredients together to form an aqueous suspension of particles. The slurry preferably has rheological properties such that the slurry easily flows under applied stress, for example, during the process of immersing the slurry in the polyurethane foam, but does not flow when the stress is removed. This slurry has inherent high yield stress and shear thinning characteristics.

After immersing the precursor foam in the aqueous ceramic slurry, the drying of the ceramic material is usually performed in a convection dryer at a temperature between 100°C and 600°C for a duration of 15 minutes to 6 hours. For process economy and high productivity, a shorter duration is ideal.

The firing of ceramic materials generally occurs at a temperature where the glass phase of the material can form and combine to produce the strength and corrosion resistance required for the final product. The firing is usually carried out in a continuous furnace for 1-3 hours, and the peak temperature above 1100°C is maintained for 15 minutes to 1 hour. Lower temperature and shorter duration can improve the manufacturing economy. However, sufficient time and temperature must be provided to achieve the required material strength and corrosion resistance.

The size of the holes is commonly referred to in the art as the number of holes of linear size, such as holes per inch. The higher the PPI value, the smaller the hole diameter.

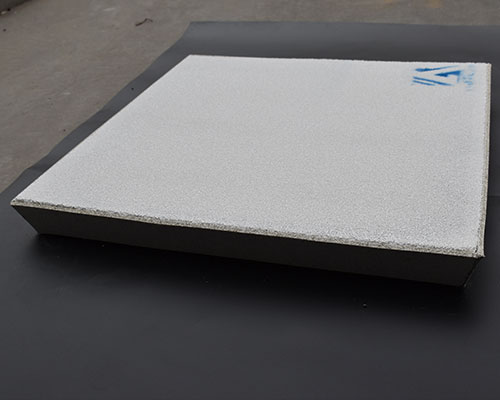

Ceramic Foam Filter product is available in all common sizes: 7″, 9″, 12″, 15″, 17″, 20″, and 23″. We offer the whole range of porosities from PPI 20 up to PPI 60 (PPI = pores per inch). Custom-made cut-to-size filters are also possible.

Alumina Ceramic Foam Filters are mainly for filtration of aluminum and aluminum alloys in foundries and cast houses. With their excellent resistance to attack and corrosion from molten aluminum, they can effectively remove inclusions, reduce trapped gas and provide laminar flow, and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.