The high temperature ceramic filter has a three-dimensional network skeleton structure, which is prepared by applying the ceramic slurry to a synthetic resin foam, it has an open-cell three-dimensional network skeleton structure, followed by drying and firing. The ceramic slurry contains 20-40 parts by weight of aluminum titanate, 40-60 parts by weight of mullite, 2-20 parts by weight of alumina and pyroxene. The high temperature ceramic filter can be used to filter molten metal.

AdTech provides an improved high temperature ceramic foam filter and its manufacturing method, which is characterized by excellent mechanical, thermal and chemical properties.

The improved ceramic foam filter is prepared from ceramic slurry containing at least 8% phosphate binder, and is used to filter molten metal. The filter is characterized by having an open-cell structure with a plurality of interconnected voids surrounded by the ceramic mesh. The filter is also characterized by being substantially free of phosphate, that is, having less than 2% of phosphate as P 2 O 5, and having individual ceramic particles that are tightly bound to make the porosity between these particles (ie, microporosity) minimize. The microporosity is less than about 5%.

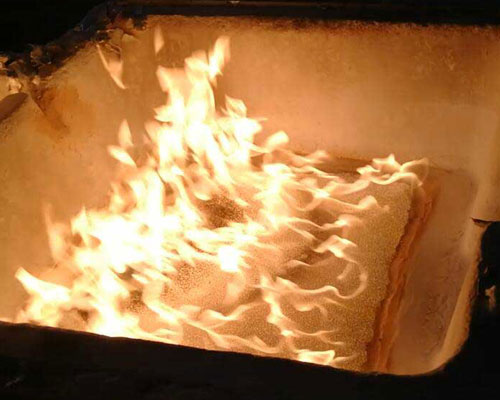

The hydrophobic, reticulated organic polymer foam, preferably polyurethane foam, is impregnated with an aqueous slurry of the thixotropic ceramic composition, the slurry including at least 8%, preferably more than 10%, of a phosphate binder. Drying and heating to remove organic components therefrom, and then firing at a high temperature to volatilize the phosphate, thereby producing a material that is substantially free of phosphate, and sintering the refractory material to produce a material with closely bound individual ceramic particles, Minimize the porosity between particles. In a preferred embodiment, firing is carried out at a temperature of about 3020°F or greater, and preferably about 3050°F or greater, to volatilize the phosphate, and then sinter the refractory. As mentioned above, the resulting ceramic foam material is essentially free of phosphates that are susceptible to chemical attack. In addition, the resulting material is characterized by improved strength characteristics and chemical durability. The preferred refractory material is alumina. However, other refractory materials can be used, such as zirconia, silicon carbide or other materials suitable for use with phosphate binders. Naturally, the specific temperature will vary from system to system.