AdTech Ceramic Filter Price is reasonable, and the filling ability of aluminum alloy liquid is improved by ceramic foam filter filtration.

Ceramic Filter Price

Ceramic Foam Filter Filtration

Removing impurity and slag: purifying aluminum alloy liquid and removing hydrogen: after filtration, the viscosity of aluminum alloy liquid is reduced, and the fluidity of aluminum alloy liquid is increased by 10% 15%. Therefore, the filling ability of aluminum alloy liquid is improved by ceramic foam filter filtration.

Before filtration, the flow of aluminum alloy fluid is turbulent, and after filtration, it becomes laminar flow (the bending of the ceramic filter is bent within the flow path), which reduces the volume of air and the two slagging.

With the filtration process, the filtration mechanism is filtered from sieve to cake, and the filtration degree of aluminum alloy is higher and higher (without exceeding the maximum filtration capacity of ceramic foam filter). For example, the aluminum alloy liquid in the combustion chamber at the bottom of cylinder head is the purest.

The scrap rate of parts is reduced.

Improvement of cutting performance of parts.

The mechanical properties of the materials were improved significantly, especially the elongation.

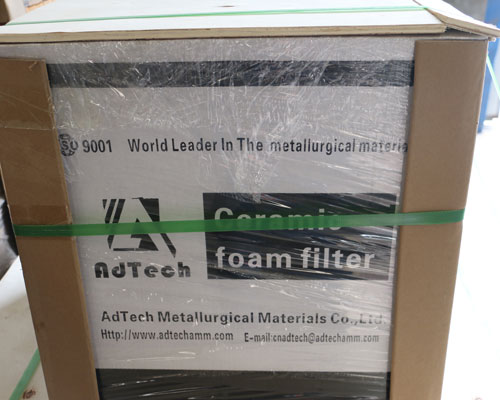

Ceramic Filter Price Selection

1: Calculate the minimum section area of the sprue.

2: Calculate the sum of cross-sectional area of runner and sum of cross-sectional area of runner.

3: Determine the location and number of filters.

4: Determine the size of the filter according to the filtration speed of the filter per unit area, the filtration capacity of the filter per unit area, the actual pouring speed, the weight of the aluminum alloy liquid passing through the filter and the purity of the aluminum alloy liquid, so as to determine the size of the filter (if the aluminum alloy liquid is too impure, multi-stage filtration is required).

The results show that the filtration rate of the filter is > the pouring speed of the aluminum alloy liquid, and the filtering capacity of the filter is > the amount of inclusions in the aluminum alloy liquid.

Generally: the filter area of the filter is 2.5-4 times of the runner section area.