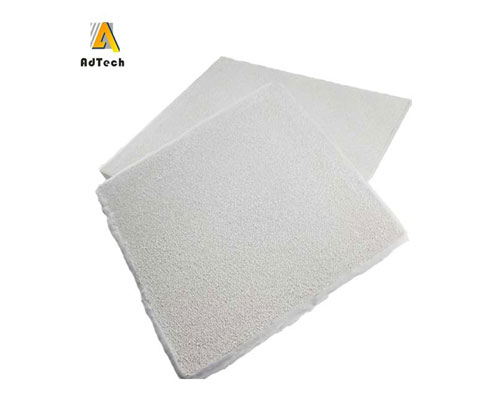

Selection of Ceramic Filter Media for Aluminum size

1. Calculate the minimum cross-sectional area of the sprue.

2. Calculate the sum of the cross-sectional area of the runner and the sum of the cross-sectional area of the inner runner.

3. Determine the placement and number of filters.

4. According to the filtering speed of the Ceramic Filter Media for Aluminum per unit area, the filtering capacity of the filter per unit area, the actual pouring speed and the weight of the aluminum alloy liquid passing through the filter and the purity of the aluminum alloy liquid, determine the size of the filter (such as aluminum alloy If the liquid is too impure, multi-stage filtration is required).

Namely: the filtration speed of the Ceramic Filter Media for Aluminum> the pouring speed of the aluminum alloy liquid the filtration capacity of the filter> the amount of inclusions in the aluminum alloy liquid

Usually: the filter area of the filter is 2.54 times the cross-sectional area of the runner.

The area where the metal passes through the filter should be large enough to not affect the pouring speed and pouring time of the mold due to the placement of the filter. Therefore, the process should be considered: slag collection factors, filter factors, and damping factors. Therefore, the ratio of the area of the cross section at the filter to the area of the normal runner is 2.5-4.0:1.

There should be a large enough space before and after the filter to collect the inclusions and also facilitate the smooth flow of molten metal.

Use ceramic foam filter, in order to prevent filtering inclusions from affecting the flow of metal, the filter size is selected according to the amount of molten metal filtered.

If the whole box of aluminum water is too much or too dirty, you can branch on the runner and use multiple filters.