Metal casting components are found in 90 percent of manufactured goods and equipment, from critical components for aircraft and automotive industry to home applications. However, molten metal used to produce metal casting in practice generally contains impurities and inclusions, which are deleterious to final cast metal products. Currently, the CFF filtration technique by using ceramic foam filter has been accepted as a successful method, so as to reduce inclusions from molten metal during the casting of metal parts.

CFF Filtration Technique

During the melting and processing of molten aluminum, a film is usually formed on the surface of the molten metal. The film is mainly composed of aluminum oxide and its alloy components, and the film is decomposed and dispersed in molten metal for internal melting, processing, and transfer to a ladle or mold during stirring.

Although it is careful when refining molten metals, some finely divided non-metallic solids are trapped in the solidified metal. Although such non-metallic impurities are harmless in some castings, they are objectionable in aluminum castings, especially when they prevent obtaining a fine finish or acting as a nucleus to form air voids.

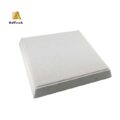

Molten metal filtration is used as a means to separate finely solid impurities suspended in the melt. AdTech’s ceramic foam filter is the most effective method for filtering molten aluminum. It can increase the initial flow rate and minimize clogging, without loss of filtration efficiency.

CFF Filter Manufacturer

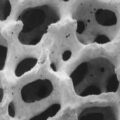

Ceramic foam filters are produced by impregnating polyurethane foam with a ceramic slurry, drying, baking and finally firing the foam in the oven. Experimental tests were carried out to the filters to measure dimensions, weight, cold compression strength, and permeability properties before the pouring process. After the pouring process, the filter was cut into several sections to measure the macro and microstructure of the filter and ensure that impurity particles captured by a filter. Thermal shock properties, obtained from pouring liquid aluminum when the CFF filter was placed in the gating system to ensure that the filters could withstand temperatures of aluminum alloys.

AdTech CFF filtration plate can be made in any shape and size, has excellent thermal shock resistance, adequate compressive strength, acceptable density, and permeability properties.