After placing the ceramic foam filter in the filter system, the filter produces a comprehensive resistance to the liquid casting alloy.

This resistance mainly includes:

Thermal resistance: The resistance caused by the temperature difference between the high-temperature molten metal and the filter.

Force resistance: At the entrance of the filter, a large stream of molten metal is diverted into many small streams of flowing molten metal. The impact flow resistance generated and the friction force generated when the molten metal passes through the filter.

The thermal resistance and the force resistance are also affected by the surface tension effect related to the wetting characteristics of the liquid casting alloy on the ceramic. In order for the filter system to filter smoothly, the above-mentioned resistance must be overcome. The measure to overcome the thermal resistance is to ensure that the liquid casting alloy has sufficient superheat. Use the heat of the molten metal to heat the filter to a temperature close to that of the molten metal. In this way, when the molten metal is close to the filter, it can still remain liquid, creating a sufficient pressure difference needed to penetrate the ceramic foam filter and overcoming mechanical resistance. In this way, the initial restriction of the filter on the molten metal will be lifted.

In order to achieve the above-mentioned purpose, the size of the filter, the cross-sectional area of the inlet of the filter, the cross-sectional area of the runner, and the static pressure head of the molten metal must be correctly selected. The setting of the filter not only achieves the best filtering effect, but also keeps the molten metal at an appropriate flow rate.

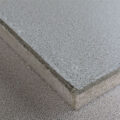

CFF filter system efficiency is related to filter cell size. By carefully controlling cell size within the filter, a more consistent filtration performance can be achieved. Typically, removal efficiency increases as filter cell size and the metal velocity in the filter decrease.

AdTech Ceramic Foam Filters are available in all common sizes: 7″, 9″, 12″, 15″, 17″, 20″, and 23″. We offer the whole range of porosities from PPI 10 up to PPI 60 (PPI = pores per inch). Custom-made cut-to-size filters are also possible.