Ceramic foam can be divided into two categories, namely, open hole (net) ceramic material and closed-cell ceramic material, depending on whether each hole has a solid wall. If the foam solid is only included in the hole, it is called an open hole ceramic material whose pores are interconnected. If there is a wall surface, the foam is called closed-cell ceramic material, and the holes are separated from the continuous ceramic matrix. However, most foamed ceramics have both open pores and a few closed pores. Generally speaking, the materials with pore diameter less than 2 nm are microporous materials, those with pores between 2 and 50 nm are mesoporous materials, and those with pores above 50 nm are macroporous materials.

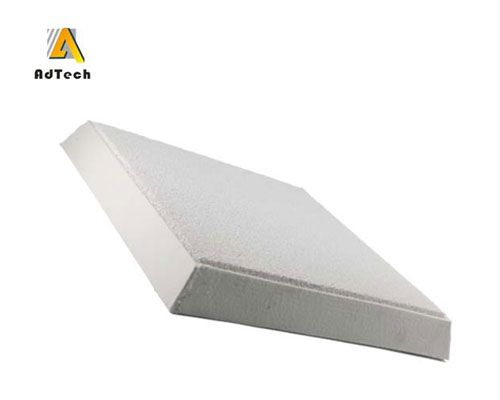

Foamed ceramic is a porous ceramic body with high porosity, which is shaped like toughened foam or porcelain foam. Because of its high porosity, large specific surface area, thermal shock resistance, high temperature resistance, and filtration adsorption property, it is widely used in the purification and metallurgy industry to filter molten metal.

Since the US invented the foamed ceramic slurry of alumina and kaolin in 1978, and successfully used for the production of porous ceramics, it has been used for aluminum alloy casting and filtration. The British, Japanese, German, Swiss, and other countries have been competing in the research and production process. The increasingly technical equipment is developing more mechanically and automatization, and has made many kinds of materials suitable for different uses, such as Al203, zrO2, SiC, silicon nitride, boride, and others. Some of them have added some minerals such as mullite, cordierite, and fly ash. The products have been serialized and formed a new industry.

Ceramic foam filters are specially designed for casting metals. Due to the formation of “cake” on the side of the entrance filter and deep filtration in the ceramic matrix, these foamed ceramic filters are effective tools to achieve the metallurgical purity of molten metal during casting. The filter also stabilizes mold filling and prevents undesirable defects in the casting. The foam ceramic filter has good thermal conductivity, stability, and sudden temperature change.