Foam Ceramic Filtration Technology

Foam ceramic filter technology came out in the late 1970s. The foam ceramic filtration technology has shown great vitality. It has been widely used in semi-continuous casting and shaped castings in the United States, Japan, Canada, the United Kingdom, France, and Switzerland. The foam ceramic filtration technology is regarded as a major breakthrough in the aluminum industry. The filtering function ...

Read More…

Read More…

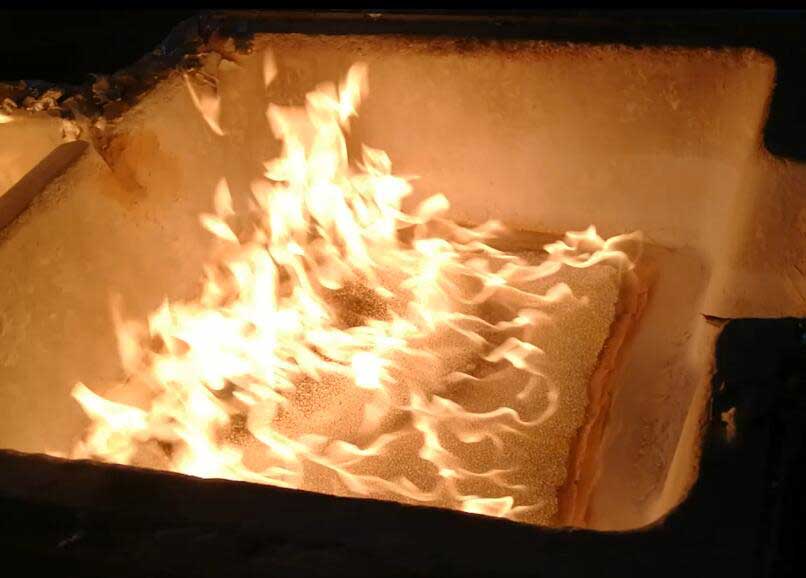

Ceramic Foam Filter Production Process

Ceramic foam filter production process includes the selection of raw materials, produce, drying, and packing. Selection of Raw Materials (1) Foam plastic is the most critical material in the raw material of ceramic foam filters. It should have sufficient elasticity, the holes should be uniform, and it should have the ability to completely restore the original state after filling with porcelain slu ...

Read More…

Read More…

CFF System

The inclusions in the aluminum ingot destroy the continuity of the metal, and they are often one of the main sources of cracks. Thereby reducing the performance of aluminum alloy, affecting the quality of casting. With the development of science and technology, the requirements for aluminum alloy materials are getting higher and higher, especially in the use of industries such as aerospace, aviati ...

Read More…

Read More…

Ceramic Foam Filters for Sale

In order to improve the quality of castings and obtain high-quality aluminum die casting parts, Ceramic Foam Filters for Sale have been used for many years. The main function of the filter is to enable many users to remove foreign materials from the molten metal. In Europe, most ceramic foam filters are used to reduce inclusions in liquid aluminum alloys. These filters are lightweight, high streng ...

Read More…

Read More…

Ceramic Filter Box

During the melting and casting of aluminum, bubbles, oxide films, and non-metallic inclusions disrupt the continuity of the metal structure. It will cause stress concentration, lower the performance of the casting, and reduce the processing performance. In order to avoid these hazards, it needs the help of the Ceramic Filter Box. AdTech offers complete degassing and filtering equipment for filtrat ...

Read More…

Read More…

Boron Nitride Ceramic Material

Boron nitride (BN) is a new type of ceramic material, it has excellent performance and great development potential. Boron Nitride Ceramic Material is widely used in machinery, metallurgy, chemical industry, electronics, nuclear energy and aerospace fields. Boron nitride is a crystal composed of nitrogen atoms and boron atoms. The chemical composition is 43.6% boron and 56.4% nitrogen, and the theo ...

Read More…

Read More…

Aluminum Silicate Casting Nozzle

Aluminum Silicate Casting Nozzle is the key parts of the continuous aluminum trip casting machine, which directly affects the quality of aluminum sheets. The caster tips have many types according to different casting machines. Casting tips determine the width of the aluminium sheet during continuous casting. Casting tip sections, in conjunction with spacers, create a cavity allowing for the flow o ...

Read More…

Read More…

Aluminum Purification Technology

The use of aluminum alloy castings is increasing, and the requirements for castings are becoming higher and higher. In addition to ensuring chemical composition, mechanical properties and dimensional accuracy, aluminum alloy castings are not allowed to have casting defects such as shrinkage holes, air holes, and slag holes. Aluminum purification technology is a comprehensive treatment of purificat ...

Read More…

Read More…

Alumina Foam Ceramic Filter

Alumina foam ceramic filter plates are very important in improving the quality of smelted aluminum alloy melts. It greatly affect the subsequent processing performance and the quality of the final product. Therefore, all countries in the world attach great importance to the purification of aluminum melt. AdTech ceramic foam filters (CFF) have substantial strength at ambient and molten aluminium te ...

Read More…

Read More…

Aluminum Degassing

The primary purpose of degassing is to remove hydrogen from molten aluminum. The aluminum degassing process can also remove other harmful substances, such as chemical inclusions or alkaline substances. AdTech degassing equipment can meet the production of aluminum products with high technical performance requirements. Aluminum degassing machine is between the furnace and the casting machine, the m ...

Read More…

Read More…