Aluminum Degassing Process

With the development of the automotive industry, more and more aluminum alloy castings are used, and the requirements for casting are becoming higher and higher. In addition to ensuring the chemical composition, mechanical properties, and dimensional accuracy. Aluminum alloy castings are not allowed to have casting defects, such as pores and slag holes. Liquid aluminum purification treatment can i ...

Read More…

Read More…

Aluminium Die Casting Process

The Aluminum Alloy Melting is an important part of the aluminium die casting process. Aluminum alloys are commonly smelted in crucible furnaces or induction furnaces. The main task of smelting is to improve the purity and metamorphic effect of the molten aluminum. Aluminium Die Casting Process The aluminium die casting process mainly includes refining and metamorphic treatment. Refining Effect The ...

Read More…

Read More…

Heat Treatment of Aluminium Alloys

Compared with iron alloys, aluminum alloys have many excellent characteristics. Aluminum alloy has a relatively low density and high specific strength, and is widely used in aircraft, automobiles, ships and aerospace industries. Aluminum has good electrical and thermal conductivity, and is an indispensable material in the electrical appliance and instrument industry. It also is an ideal material f ...

Read More…

Read More…

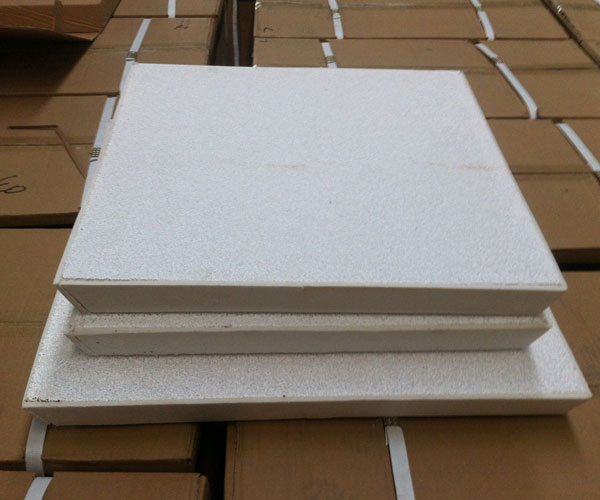

Ceramic Filters for Foundry

The ceramic filters for foundry use filtration technology to reduce impurities and inclusions in the molten aluminum before casting. The quality of the liquid aluminum treatment will affect the product quality of the ingot, which in turn affects the product quality of the subsequent processed materials. Therefore, the ceramic filter for foundry technology is an important part of the aluminum proce ...

Read More…

Read More…

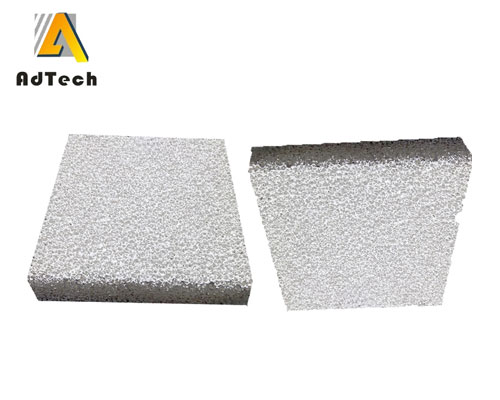

Ceramic Foam Filters

The ceramic foam filter for casting can effectively remove large inclusions in the liquid aluminum, and absorb micron-sized fine inclusion particles. It plays a role in improving surface quality, product performance, microstructure, and yield. Molten aluminum filters are widely used in aluminum profiles, aluminum foil, aluminum alloy and other production fields. The foam filter uses a three-dimens ...

Read More…

Read More…

Aluminium Purification Methods

Aluminium purification methods divide into furnace treatment and online purification. Over the years, aluminum alloy products have continuously improved the internal quality of the ingot. Especially the cleanliness, and melt purification is the main means to improve the purity of aluminum. Furnace Treatment The molten aluminum purification methods in the furnace mainly includes gas refining, flux ...

Read More…

Read More…

Purification of Aluminium

The quality of the aluminum melt is very important, it greatly affects the subsequent processing performance and the quality of the final product. Therefore, all countries in the world attach great importance to the online purification of aluminium. Reasons for Aluminum Pollution There are many reasons for aluminum pollution. On the one hand, in the melting process, aluminum is exposed to the furn ...

Read More…

Read More…

Foam Ceramic Filter

Inclusions and gases in the metal have a significant impact on the strength, fatigue resistance, corrosion resistance, stress corrosion cracking performance. Effectively controlling the oxidized inclusions in the melt can improve the quality of cast rods and rolled plates, it has become a common goal pursued by metallurgy, foundry and materials industry in various countries. Currently, filtration ...

Read More…

Read More…

Aluminium Degassing

Hydrogen embrittlement is a phenomenon in which a metal becomes brittle due to hydrogen absorption, its plasticity decreases, and it breaks on its own. This ruptured form of material is bound to cause unexpected accidents and pose a great threat to safety. With the extensive application of metal materials, most aluminum foundries use a rotary degassing system to remove hydrogen from molten aluminu ...

Read More…

Read More…

Molten Aluminum Refining Degassing

When the hydrogen content in the aluminum casting reaches a certain value, its mechanical properties will be seriously reduced. And hydrogen embrittlement will occur, causing the casting to be scrapped. In order to prevent cracking defects caused by hydrogen in the alloy, AdTech offers molten aluminum refining degassing system to remove hydrogen from the aluminium material. AdTech molten aluminum ...

Read More…

Read More…