With the development of the automotive industry, more and more aluminum alloy castings are used, and the requirements for casting are becoming higher and higher. In addition to ensuring the chemical composition, mechanical properties, and dimensional accuracy. Aluminum alloy castings are not allowed to have casting defects, such as pores and slag holes. Liquid aluminum purification treatment can improve the overall quality of aluminum alloys. The refining effect has an important influence on the formation of holes and inclusions, and directly affects the physical and mechanical properties of aluminum alloy castings. Therefore, we must pay attention to the gas and inclusions in the aluminum liquid. And Aluminum Degassing Process can remove the gas and inclusions in the aluminum liquid.

The gas in the liquid aluminum is mainly hydrogen. Hydrogen is almost insoluble in solid aluminum, but it is very soluble in liquid aluminum. Because of the different solubility, hydrogen tends to escape from the melt. When the hydrogen pressure is greater than the surface tension and the hydrostatic pressure, bubbles are formed, which in turn creates pinholes in the casting. There is a strong interaction between the inclusions in the aluminum alloy and the gas. Common non-metallic impurities in liquid aluminum are oxides, nitrides, carbides, borides, etc. And the hydrogen content in the aluminum liquid is greatly affected by the inclusions. In the case of the same hydrogen content, the higher the inclusion content, the higher the pinhole rate. On the contrary, when the impurity content in the aluminum liquid is very low, the hydrogen content is also very low. Therefore, it is equally important to remove impurities and degas simultaneously.

Aluminum Degassing Process

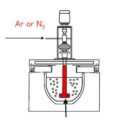

The aluminum degassing unit is installed between the holding furnace and the casting machine. Blow the Nitrogen into the molten aluminum alloy, and the gas is shredded by the rotating graphite rotor in the degassing tank. Then a large number of dispersed bubbles are formed, so that the liquid aluminum alloy is in full contact with nitrogen in the treatment tank. According to the air pressure difference and the principle of surface adsorption, bubbles absorb hydrogen and oxidized slag. And then the bubbles rise to the surface of the melt to form scum. Then molten aluminum alloy flows from the outlet of the degassing unit to the casting machine. The liquid aluminum alloy continuously enters the degassing device, and nitrogen is continuously blown in. With such a purification process, the degassing machine can achieve the purpose of purifying the aluminum alloy.

Before the molten aluminum enters the degassing equipment, the worker should switch off the heating element. When the temperature of the heater is close to the molten aluminum. Inject the inert gas into the rotor, and then fill the molten aluminum into the degassing box.