Aluminium purification methods divide into furnace treatment and online purification. Over the years, aluminum alloy products have continuously improved the internal quality of the ingot. Especially the cleanliness, and melt purification is the main means to improve the purity of aluminum.

Furnace Treatment

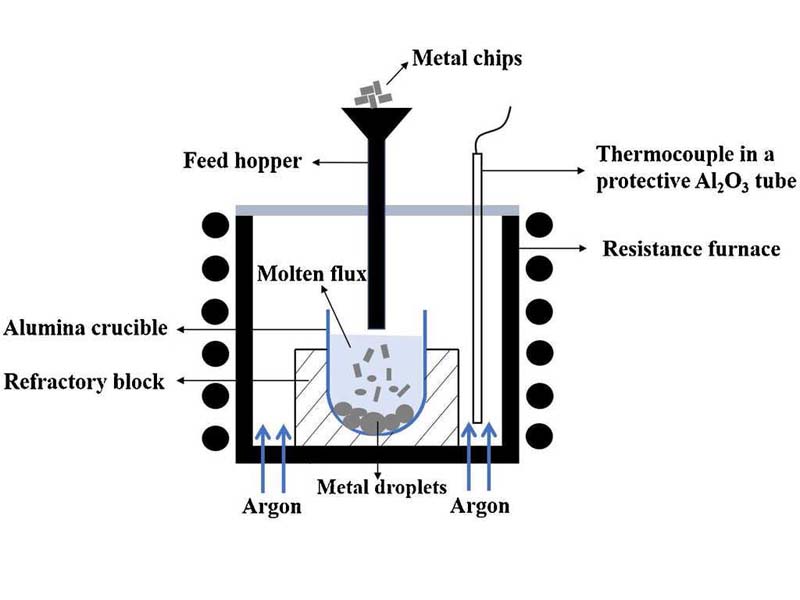

The molten aluminum purification methods in the furnace mainly includes gas refining, flux refining and powder refining.

The advanced furnace purification treatments abroad adopt automatic control. There are two representative ones. One is to insert multiple spray guns from the furnace top or furnace wall into the furnace melt for powder spraying or gas refining. However, due to the shortcomings of this technology, the spray gun is fragile and difficult to seal, it has not been widely used. The other is to install a plurality of replaceable vent plugs evenly on the bottom of the furnace. And the computer controls the refining airflow and refining time. This method is a relatively effective furnace treatment method.

Aluminium Purification Methods

The purification effect of the furnace treatment on the aluminum alloy is limited. To further improve the purity of the melt, especially to further reduce the hydrogen content and remove non-metallic slag. It needs to adopt efficient online purification technology.The online degasser device is the key research and development object of major aluminum melting casting plants. There are many types. The typical devices include fixed nozzles such as MINT and rotating nozzles such as SNIF and Alpur. These degassing devices all use N2- or Ar as the refining gas, which can effectively remove the hydrogen in the aluminum melt. For example, add a small amount of Cl2, CCl4 or SF6 to the refining gas, which can also remove alkali metals and alkaline earth metals in the aluminum.

Filtration is the most effective and reliable means to remove non-metallic inclusions in aluminum melt. Most aluminum foundry adopts foam ceramic filter plates. The technology has developed rapidly. In order to meet the requirements of high-quality products on the quality of the melt, the pore size of the filter plate is getting smaller and smaller. Adtech ceramic foam filters have been developed from 10, 20, 30, 40, 50ppi to 60ppi.