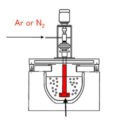

The rotating degassing purification method uses a rotating nozzle to spray gas flux from the bottom of the aluminum alloy melt. During the rotation of the nozzle, the fluid sprayed from the nozzle blades produces a strong stream, which can produce more than a single tube Or multiple tubes with smaller bubbles, at the same time, the high-speed rotation of the rotating nozzle can make the bubbles uniformly distributed and dispersed, and they are ejected radially first, and float to the surface along a spiral path under the combined action of centrifugal force and buoyancy force, thereby effectively The gas-liquid contact interface is enlarged, the renewal of the gas-liquid interface is promoted, the contact action time of the gas-liquid interface is prolonged, and the kinetic conditions of the purification of the aluminum alloy melt are significantly improved, so that an excellent purification effect can be obtained. It has become a recognized high-efficiency hydrogen removal technology for aluminum alloy melt at home and abroad, and is favored by Shiduo users.

The Rotating Degassing Purification method of spraying gas flux with a rotating nozzle has become an important development trend of aluminum alloy melt purification technology.

There have been many patented products abroad, such as: the SNIF method of the United Carbide Corporation of the United States, the ALPUR method of the French Pisigne company, the RDU of the Inin Foseco company, the RID method of the United States Hitchcock publicly available, and the rotary jet flux developed by the Australian Pyroteck company Series equipment of law.

Based on the introduction of some foreign advanced purification technologies and equipment, domestic research on aluminum alloy melt purification technology has also begun. For example: Dalian University of Technology and East China Aluminum Processing Plant designed and developed DUT89 aluminum liquid purification equipment, Southwest Aluminum Processing Plant digested and absorbed MINT after it was modified and developed DFU, Northeastern University and Shijiazhuang Aluminum Plant developed DCLJ refining equipment, and AdTech’s online Degassing system and filtering equipment, etc.