There are mainly two purification methods for removing impurities: flux method and molten aluminum filtration method. Due to the interaction between inclusions and hydrogen in liquid aluminum, hydrogen removal and purification methods for aluminum have varying degrees of impurity removal. Because the degassing method used to remove impurities is very limited, a molten aluminum filtration method based on the removal of impurities must be adopted.

Purification Methods for Aluminum

The essence of flux purification is that when a flux is used to purify molten aluminum, the inclusions will automatically transfer from the melt to the flux due to the different wettability between the contacting phases. The removal effect of impurities is directly related to the physical and chemical properties of the flux itself, and also depends on the amount of flux, the contact conditions between the flux and the melt, and the purification process conditions such as temperature. In the past, flux treatment was mainly based on accumulated experience, and the thermodynamic and kinetic conditions of impurity removal and purification, as well as the reasonable design of flux composition and treatment process, were rarely studied systematically.

AdTech focuses on R&D, production, and sales of refining agents for the degassing and slagging of molten metal in the aluminum alloy casting process. AdTech’s refining agents use unique technology to improve the traditional removal of molten metal The effect of gas slag removal has been applied to the casting and rolling process of many series of aluminum alloy products. High-efficiency refining agents have been successfully applied in practice and have effectively played the role of impurity removal and flux purification.

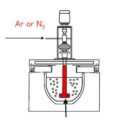

The main purpose of filtering molten aluminum is to make the molten aluminum flow through a certain medium, and then the medium will capture the inclusions according to a certain mechanism, and cut off the hydrogen adsorbed on the impurities to achieve the purpose of purification, which is an effective way to remove impurities method. At present, according to the form of the filter, it can be divided into three types: mesh filter, particle filter and porous ceramic filter. Porous ceramic filters are divided into hard ceramics (microporous) and foam ceramics. According to the filtration mechanism, the porous ceramic filter can be divided into filter cake filtration mechanism, deep filtration mechanism, and porous ceramic filtration.

Since 2012, AdTech has focused on the research and development, production and sales of high-absorption ceramic foam filter (CFF) used in aluminum alloy casting. AdTech’s ceramic foam filter plate technology has been widely accepted by the market. The filtration effect of AdTech foam ceramic filter plate depends on the pore size of the filter plate, the size and type of inclusions (density, wetting characteristics) and the speed of the molten metal through the filter plate.