The Aluminum Alloy Melting is an important part of the aluminium die casting process. Aluminum alloys are commonly smelted in crucible furnaces or induction furnaces. The main task of smelting is to improve the purity and metamorphic effect of the molten aluminum.

Aluminium Die Casting Process

The aluminium die casting process mainly includes refining and metamorphic treatment.

Refining Effect

The purpose of refining is to purify aluminum liquid through degassing and slag removal. There are many refining methods, such as floating method, solvent method, filtration method.

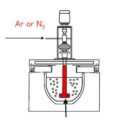

Floating refining is to use active other (chlorine salt), inert gas (nitrogen, argon), or oxidizing gas (sodium nitrate) as the refining agent, continuously introducing bubbles into the aluminum liquid, and oxidizing inclusions and hydrogen are taken away by bubbles. Filtration and refining is to pass aluminum liquid through a filter (ceramic filter plate) to separate solid inclusions suspended in the aluminum liquid. The floating refining method has a good degassing effect, and the solvent refining method and the filtering refining method have a better effect of removing inclusions. Studies have shown that gas-solvent mixture refining is better than refining alone. Therefore, AdTech has developed online degassing and filtration equipment specifically for aluminum foundry.

Metamorphic Treatment

Thick-walled silicon crystals are prone to appear in thick-walled castings of aluminum alloys containing more than 6% silicon, which reduces their mechanical properties. The modification treatment can change the eutectic silicon from coarse flakes to fine fibrous or layered flakes, thereby it can improve alloy performance. Potassium, sodium, strontium, antimony, rare earth elements all have a metamorphic effect. Among them, sodium salt has the best effect of deterioration, but sodium salt has a short effective time and low absorption rate, which brings many inconveniences to production. Considering the effect of metamorphosis comprehensively, the application of strontium metamorphosis has been fully paid application.

Modifiers generally adopt three methods: pure metal, intermediate alloy and solvent. Normally, the sodium modification agent adopts solvent (NaF) method, strontium modification adopts Al-Sr intermediate alloy method, and rare earth modification adopts intermediate alloy and solvent method. Modification treatment is a necessary process for the production of aluminum-silicon alloy castings. AdTech provides Sr modifiers and metal additives for aluminum foundries.