Rotary degassing refining equipment

Advantages of ADTECH online degassing and refining equipment

The degassing rotor, heater protection sleeve, and thermocouple protection sleeve used in the online rotary degassing refining equipment are all made of silicon nitride ceramics. This material is composited with graphite and SiC-silicon nitride, which are mostly used in the aluminum industry. Compared with materials such as aluminum alloys, it has strong advantages in aluminum corrosion resistance, thermal shock resistance, oxidation resistance, wear resistance, and mechanical strength.

As a well-known manufacturer of online rotary degassing refining equipment in China, the lining and equipment of the aluminum liquid degassing box provided by Adtech online degasser are mainly used for the purification of the melt produced by aluminum products. According to the function, it is mainly divided into a single-rotor degassing box and a double-rotor degassing box.

About service life

The life of other graphite rotors commonly used in the world is about 3 months. However, after 2 weeks of actual use, due to the material properties of the graphite rotor, the shape change caused by wear will cause the degassing efficiency to decrease. However, the performance of the silicon nitride rotor will not change, and it has a long-term stable degassing effect.

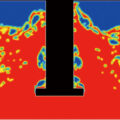

degassing unit