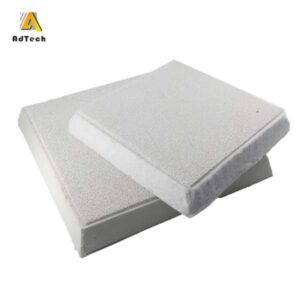

The filtration of the open cell foam filter material can remove most of the impurities such as inclusions and gases in molten metal, and improve the inherent quality of metal materials such as strength. It is especially important in electronic components, metals for wires, and metals for precision casting. The foamed ceramic filter used in the filtration of liquid-casting alloys should have the following properties:

1 with suitable refractoriness and low thermal expansion coefficient, so that it will not soften, deform and crack under the long-term action of high-temperature molten metal;

2 with sufficient mechanical strength at room temperature and high temperature makes it able to withstand vibration during transportation, extrusion, and the impact of high-temperature molten metal during use;

4 it has excellent high-temperature chemical stability so that it is not eroded by high-temperature molten metal and avoids contamination of metal. liquid.

5 High-temperature gas filtration, high-temperature flue gas dust removal, high-temperature gas purification, and other high-temperature gas filtration must use high-temperature-resistant the open cell foam filter material

the open cell foam filter material

6 Filter core of radioactive material

A large amount of radioactive waste is produced in power plants, etc., which can become chemically stable solid powder after combustion, and can be solidified by the porous ceramic filter, which is convenient and economical to store.

Insulation material

The high porosity of the open cell foam filter material makes it have a small density and low thermal conductivity, resulting in a huge thermal resistance and a small volume heat capacity, and it has become a traditional thermal insulation material. If its internal pores are evacuated, it will become the world’s best thermal insulation material – “super thermal insulation material”, and its heat transfer coefficient is a thousand times lower than that of rigid polyurethane foam. This material can be used for advanced insulation, such as cold containers. More advanced porous ceramic insulation materials can also be used for space shuttle shell insulation; also used in missile heads and as components of forced sweating systems

Catalyst carrier

The high specific surface area of the porous ceramic filter makes it have good adsorption capacity and activity. As a catalyst carrier, it can increase the effective contact area and improve the catalytic effect. At the same time, due to its excellent thermal shock resistance and corrosion resistance, it can be used in extremely harsh environments. Therefore, it is widely used in automobile exhaust gas treatment and chemical towers and is also used as an enzyme carrier. At present, the research focus of the open cell foam filter material as catalyst carriers is on inorganic separation catalytic membranes, which combine the separation and catalysis properties of porous ceramic materials and have broad application prospects.

Sound-absorbing material

the porous ceramic filter has connected open pores. When sound waves are introduced, they will oscillate in the small pores, and the friction and obstruction of the vibration will inhibit the propagation of sound waves, resulting in sound attenuation and sound absorption. It is a good material to eliminate noise pollution and benefit people’s physical and mental health. the open cell foam filter material as sound-absorbing material requires a small pore size (20~150μm), relatively high porosity (>60vol%), and high mechanical strength. The excellent fire resistance and weather resistance of ceramics make them suitable for sound insulation of transformers, roads, bridges, etc. Now it has been used in high-rise building tunnels, subways and other occasions with extremely high fire protection requirements, as well as TV transmission centers, theaters, and other occasions with high sound insulation requirements, and the effect is very good.