The high-efficiency ceramic foam material for filtering molten aluminum has an open-cell structure with a plurality of interconnected voids surrounded by a mesh of ceramic material. The air permeability of the filter is 400 to 8000×10-7 cm2. In addition, the filter has a porosity or porosity of 0.80 to 0.95, characterized by 5 to 45 pores per linear inch, and the effective range of the filter thickness is 1/2 to 4 inches.

Under normal circumstances, the finer filter has an air permeability of 400 to 2500×10-7 cm2, a porosity or porosity of 0.80 to 0.95, and 20 to 45 pores per linear inch, especially in a filter of 5000 Series of aluminum alloy. However, if the input metal is particularly dirty, the metal should be preliminarily filtered through a coarse ceramic foam filter with a pore size of 10 to 20 ppi and a larger gap. This can be achieved by providing a single ceramic filter with a certain level of performance or by using a series of filters with different porosities.

The low cost and easy preparation of the ceramic foam filter make the filter convenient to use on a disposable basis. Another distinguishing feature of filters is that they should have basic structural uniformity. In order to provide an effective filter for molten metal, the ceramic foam material for filtering molten aluminum must have a high degree of structural uniformity. Therefore, although a certain proportion of plugged pores is useful and desirable because they increase the tortuosity of the flow path, these plugs should be evenly distributed throughout the ceramic body, rather than grouped together. Blocked packets will only lead to channeling and inefficient filtering.

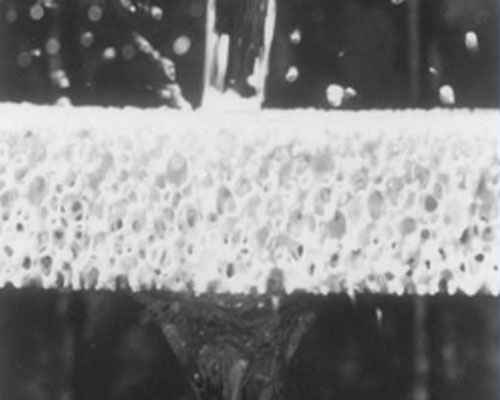

The ceramic foam is made of an open-cell flexible foam material having a plurality of interconnected voids surrounded by a web of said flexible foam material. Typical materials that can be used include polymer foams, such as polyurethane foams, and cellulose foams. Generally, any combustible organic plastic foam material that has resilience and can restore its original shape can be used. The foam must be burned or volatilized below the firing temperature of the ceramic material used. Naturally, the characteristics or size of the polymer foam should roughly correspond to the desired size of the resulting ceramic foam material. Generally, since this is the desired thickness of the ceramic foam material, a foam material with a thickness of 1/2 inch to 4 inches is used.