The aluminium flux purification of molten aluminum is one of the measures to ensure high-quality aluminum alloy products, and it is also the main means to improve the overall quality of aluminum alloys. The refining effect of molten aluminum has an important influence on the formation of pores, shrinkage cavities and inclusions, and directly affects the physical and mechanical properties of aluminum alloy castings. Without high-quality molten aluminum, even if the subsequent processing is advanced, defects will always exist in the product once they occur, and high-quality castings are difficult to obtain. Therefore, we must pay attention to the gas and inclusions in the molten aluminum, and take measures to remove the gas and inclusions in the molten aluminum.

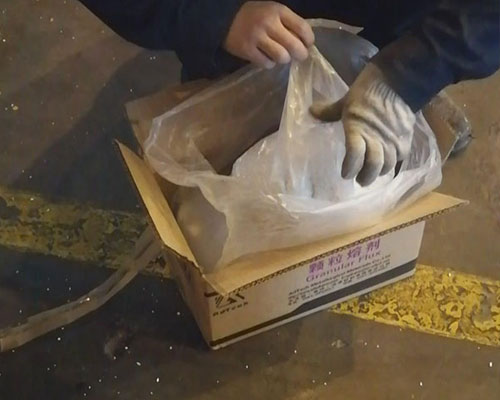

Aluminium Flux Purification

There is a strong interaction between the inclusions in the aluminum alloy and the gas, and the hydrogen content in the molten aluminum is greatly affected by the inclusions. When the inclusion content is 0.002% and 0.02%, the corresponding hydrogen content is 0.2mL/100gAl and 0.35mL/100gAl.

In the case of the same hydrogen content, the higher the inclusion content, the higher the pinhole rate. On the contrary, when the impurity content in the molten aluminum is very low, the hydrogen content is also very low. Even if hydrogen is artificially introduced, it will automatically precipitate and quickly return to its original content. Even if a small amount of inclusions exists, it can significantly reduce the critical concentration of stomata.

On the other hand, in the absence of inclusions, the critical hydrogen concentration to form pores can reach 0.3mL/100gAl. Therefore, the removal of impurities and gas should be carried out at the same time, which is equally important.

Current status of aluminum alloy melt purification technology, the comprehensive treatment of liquid aluminum purification and grain refinement is the basic problem for obtaining high-quality aluminum purification of molten aluminum alloys. According to the different production links, the purification treatment of molten aluminum can be divided into furnace treatment and out-of-furnace treatment. The aluminum alloy furnace treatment can be divided into adsorption purification technology and non-adsorption purification technology according to the purification mechanism.

The purification of the adsorption method mainly relies on the effect of adsorbing oxidized inclusions produced by the refining agent, and at the same time, removes the oxidized inclusions and the hydrogen attached to the surface to achieve the purpose of purifying the molten aluminum. Non-adsorption purification relies on other physical and chemical effects to achieve the purpose of purifying molten aluminum. The purification effect of the adsorption method only occurs on the adsorption interface, and the purification effect of the non-adsorption method acts on the entire aluminum liquid at the same time.