Light transmittance is an effective non-destructive testing method for aluminum cast ceramic filter plate products and filter area, and it is also another important indicator to measure product quality indicators. The higher the light transmittance, the fewer blind holes, and the more filter holes, the better the filter effect. All the light transmittances of the foam ceramic filter plates produced by our factory are above 95%, which does not take into account the reinforcement of each filter plate and the area of the surrounding edges.

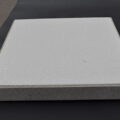

Porosity, pore uniformity, compressive strength, and thermal shock performance are the four important physical and mechanical performance indicators of foam ceramic filter products. Porosity refers to the percentage of the volume of the cavity plate product to the total volume of the filter plate product. The porosity per unit volume determines the porosity of the foam ceramic filter plate. The greater the porosity, the greater the flow rate of the filter plate, and the stronger the filtering capacity, and vice versa.

Choose Aluminum Cast Ceramic Filter

In addition to the geometric size, strength, chemical stability and thermal stability of the ceramic foam filter for casting, its filtering effect depends to a large extent on its internal structure.

At present, PPI (pores per inch) represents the pore size of the ceramic foam filter plate. The 40 PPI foam ceramic filter plate filter can remove 5-micron inclusions. Whether the particles can be removed depends on the probability of collision, and also on the ability of the filter to adsorb particles.

When selecting the pore size of the filter plate, priority should be given to product quality requirements. For civil profiles, such as cast rods and cast plates, please select 10-40ppi filter plates according to product category and melt cleanliness. High-grade aluminum foil, tin can plate and space materials require 30-80 PPI filter plates. The actual selection of the filter plate depends on the user’s practice and experience, combined with its use conditions. Finally, whether the cleanliness of the product meets the quality requirements is used as a measure.