Ceramic filter plates for foundry are mainly used in the purification process of aluminum and aluminum alloy production. As the quality requirements for aluminum products increase, the application of ceramic filter plates will become more and more extensive. Ceramic foam filters use the formulas and processes of many foreign companies. It is carefully developed using foreign advanced production equipment and some raw materials. Of course, Adtech ceramic foam filter plates for foundry are of high quality.

The ceramic filter for foundry separates the inclusions through three filtration mechanisms for sieving, filter cake and deep bed filtration of molten aluminum.

Ceramic Foam Filter Plates Filtration Mechanism for Foundry

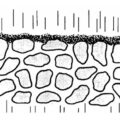

Mechanical filtration (sieving): When the size of the inclusions is larger than the aperture of the filter plate, the filter plate acts like a sieve to prevent the inclusions from passing through. The traditional glass fiber cloth filter uses this mechanism.

Sediment layer filtration (filter cake): After the previously blocked inclusions form a continuous layer on the surface of the alumina ceramic foam filter plate, the pore size used for filtration is no longer the pore size of the filter plate, but the pore size of the new filter membrane. Form a cake layer. As the filter cake layer becomes thicker, the gaps thereon become smaller and smaller, and many inclusions will be sandwiched on the surface and internal gaps of the filter cake layer. At the same time, the resistance of the filter plate to the molten aluminum continued to increase. After reaching a certain level, it is difficult for molten aluminum to pass through the filter plate. At this time, the filter plate should be scrapped. During the filtration process, the obvious change into the cake mode is the gradual increase in the pressure of the molten aluminum.

Deep bed filtration: When inclusions smaller than the pore size of the filter enter the filter plate together with the molten aluminum, they will be captured by the inner wall of the pore size of the filter plate. The thicker the filter plate, the better the effect of the model. This mode can filter out inclusions with a size of about 20um.