Problems with aluminum Degassing in China

1. Lack of attention to process conditions

This is the most important point and the one that is most easily overlooked by everyone.

point. Because the products of each factory are different, the selection of non-standard equipment must be based on product requirements and must meet the production process

Require. However, at present, various equipment manufacturers are eager to carry out their equipment. Serialization and standardization while neglecting to study the process conditions of each production plant parts and the actual production situation is not tailored for the user are the most suitable for The equipment with its characteristics, so its use effect can be imagined.

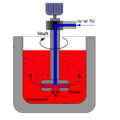

aluminum degassing

2. Improvement suggestions for domestic rotary jet aluminum degassing in China

2.1 The problem of short service life of spare parts The service life of spare parts is closely related to the development of domestic materials Guan recommends equipment manufacturers, equipment users, and material experts in the industry Discuss and test the usage situation and actively track foreign advanced Technology strives to solve these technical problems as soon as possible.

2.2 The problem of a large amount of aluminum in the box memory

Based on the current box tipping, develop the overall tipping removal system

gas equipment. The equipment is tipped over at a specific time before the end of casting and will be stored The aluminum liquid in the box is completely injected into the launder to complete the casting. It can solve the problem of the box. Body memory aluminum problem. At the same time must consider heating during tipping The boiler and graphite components continue to work to ensure that this part of the molten aluminum is the same as the previous one (Aluminum liquid) The process method is consistent to ensure that the final cast-aluminum ingot is full meet the quality requirements.

2.3 The problem of turbulent flow on the surface of molten aluminum

The diameter and rotational speed of the graphite shaft, the internal structure of the box, the structure of the graphite nozzle, and the depth of The factors of turbulent flow on the liquid surface can therefore be considered without affecting the Minimize straightness of the graphite shaft while maintaining the service life and degassing effect. diameter and rotation speed, and realize the forward and reverse rotation of the graphite shaft within the cycle time to avoid Eddy currents appearing on the surface of the aluminum-free liquid. The section of the degassing chamber in the box can be set The irregular polygons cause the graphite shaft to move during the stirring process. The velocity vector changes periodically, to avoid the vortex to the greatest extent. flow phenomenon occurs.