Although the aluminium degassing system is becoming more and more perfect, there are still some shortcomings in some equipment

1. Gas control system

Either inert gas (nitrogen or argon) or inert gas and Chlorine mixed use is equipped with refined gas, emergency gas, inert cover Gas, and other pipelines, each pipeline is equipped with pressure and flow adjustment devices. When the refining gas pressure is abnormal, it will alarm and automatically switch to the emergency gas circuit. Add 1 chlorine gas control cabinet and components in the cabinet when it needs to be mixed with chlorine gas for refining All are made of corrosion-resistant materials and equipped with an imported chlorine leakage alarm The instrument can automatically alarm once the chlorine gas leaks to avoid safety accidents.

2. Electronic control system

The electronic control system generally adopts PLC centralized control and is equipped with an electric heating system. system, graphite component speed control system, lifting system, refining gas control systems, and alarm systems. The electric heating system adopts a special intelligent instrument The table can realize a multi-segment curve heating oven and alarm when the temperature of molten aluminum is abnormal. During the production process, it can be displayed on the man-machine interface to realize remote control. system. The speed control range of graphite components varies from manufacturer to manufacturer. 0~400rpm, 0~600rpm, 0~800rpm According to the use of multiple manufacturers, when the speed is below 400rpm, it can be completely To meet production requirements If a high-speed operation is used, the graphite shaft will be accelerated wear and shorten its service life. The electronic control system has three levels: high, medium, and low. In this configuration, users can choose according to the actual situation.

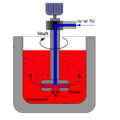

aluminium degassing system

3. The shortcomings of rotary jet online the aluminium degassing system

3.1. Short service life of equipment components

The biggest problems in aluminum production enterprises are in the production process

Sudden failure of graphite components or heating system elements thus having to stop production or make do with production until the end of a casting run. now more and more

Many manufacturers choose graphite components made of German SGL graphite and its use

The service life is longer than that of domestic graphite components, but due to the cost of imported materials High cost, long lead times, and supply shortages are all thorny issues. add

The service life of the heater protection sleeve in the thermal system, especially it is quality

Quantitative instability is what makes many people powerless, often without any prior

The mega will be suddenly damaged, which will greatly affect normal production. These problems are not It will be difficult to improve the performance of domestic equipment.