The three-rotor degassing box is specially designed for on-line degassing of launders with large aluminum flow, high air content and high inclusions. It has three stirring rotors, which can independently control the speed and gas flow, and can provide a strong degassing and refining capacity for more molten aluminum. The equipment is connected to the launder, and the three rotors of the equipment can be lifted as a whole. And it can be rotated at a certain angle to facilitate the replacement of graphite accessories, while the filter plate is used on the degassing tank.

The flow cell of the three-rotor degassing box is divided into three independent degassing spaces, corresponding to the three rotors, thus forming a three-stage degassing. The degassing system corresponding to each rotor is equipped with independent slag and slag, which is convenient for slag separation. The three rotors can be independently controlled and degas continuously layer by layer. The good insulation design of the equipment provides 24-hour online uninterrupted degassing. It can improve the online degassing and purification of large flow aluminum liquid and improve the efficiency of liquid aluminum degassing.

The three-rotor degassing box has a gas underpressure alarm function. When the pressure of the inert gas supply source drops to a limited pressure, it can automatically alarm and remind the operator to change the gas source through a warning light to avoid the occurrence of unqualified aluminum liquid due to lack of gas. The device has three rotors. When the equipment is used as an online degassing device, please prepare a backup air source in advance so that it can be replaced in time when the pressure is low.

The three-rotor air supply is large. It is recommended to establish a gas supply center to provide high-purity, nitrogen. Using nitrogen or argon as the degassing medium, the advanced degassing principle greatly reduces the elimination. The flow of inert gas is controllable and can be set optimally, which can greatly reduce the waste caused by bubbles and inclusions, greatly increase the yield and improve the mechanical properties of castings.

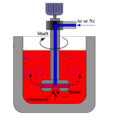

The degassing principle of the three-rotor degassing box is to stir the aluminum liquid through the controllable rotating graphite shaft, and at the same time inject the measured inert gas into the aluminum liquid through the rotor, and make it break into tiny bubbles, so that they are evenly dispersed in the aluminum liquid. In the liquid. In molten metal, the gas partial pressure of the bubbles is zero. Due to the high partial pressure of hydrogen in the molten aluminum, the hydrogen in the molten aluminum continuously diffuses into the bubbles, and at the same time, some non-metallic inclusions in the molten aluminum are adsorbed on the surface of the bubbles.