At present, online degassing of molten aluminum is widely used for molten aluminum purification. The on-line degassing equipment produced by Adtech is installed between the furnace and the casting machine to eliminate hydrogen and other residues in molten aluminum and its alloys, which affect their quality and mechanical properties. The average degassing efficiency was 60%.

In order to make online degassing aluminum work efficiently, the following points should be paid attention to:

The degassing device must have good air tightness, be less affected by climate, produce less slag, and will not form secondary pollution. When the degassing box is not well sealed, the water vapor in the air will easily enter the furnace to form hydrogen absorption. The early degassing unit mainly used high purity nitrogen as cover gas to reduce hydrogen absorption, but it was also affected by the weather to a certain extent. Therefore, in order to improve the degassing efficiency and reduce the impact of climate, the degassing equipment is required to have good sealing performance.

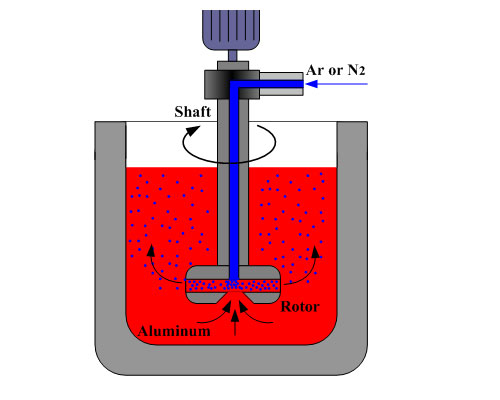

It is required that the bubbles in the degassing tank are evenly dispersed and the liquid level will not drop significantly. When the total flow rate and pressure of the process gas in the degasser remain unchanged, the larger the number of bubbles, the larger the contact area between the process gas and the melt. Therefore, the smaller the bubbles (equivalent to the more bubbles), the more bubbles. The larger the contact area is, the more favorable the diffusion of hydrogen into the process gas and the purpose of hydrogen removal can be achieved. The rotor must have sufficient stirring power so that the bubbles can move at enough speed to disperse the entire bath, but excessive rotor speed will cause the liquid surface to roll and may cause slag to re-enter the melt.

The rotor structure of degassing unit is required to have sufficient stirring capacity. The rotor rod and rotor impeller must have reasonable structure. The diameter of impeller should be increased and matched with the appropriate speed to increase the stirring force of rotor.

High purity of process gas is required and it is impossible to produce slag and absorb hydrogen from melt. Generally, the control of process gas purity mainly includes two parts, one is the control of gas source, the other is the control of leakage of all pipelines and instruments through which the gas passes. Generally, the purity of the treated gas source must reach 99.999%, the water content should be less than 4 × 10-6, and the oxygen content should be less than 5 × 10-6. Excessive water and oxygen in the process gas can lead to slagging and hydrogen absorption.

In order to ensure that the melt has enough residence time in degassing device, a certain amount of molten pool is needed. The rotor of degassing unit should be melted to a certain depth. The immersion depth of rotor is directly related to whether the whole molten pool can be completely covered by process gas, which has a more obvious effect on degassing efficiency. Generally, the immersion depth of the rotor and impeller should be greater than 500 mm, and the distance between the impeller and the bottom of the molten pool should be 50-100 mm.