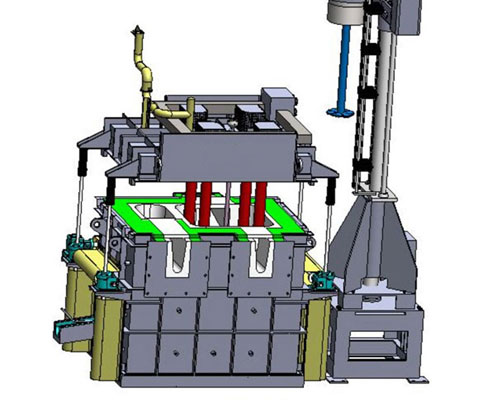

The online degassing equipment mainly processes molten aluminum that contains a certain amount of hydrogen and other residues (alkali metals, slag inclusions), which are removed after being processed by the degassing equipment. The online degassing equipment of aluminum melt uses the impeller of the graphite rotor to break up the bubbles in order to obtain tiny bubbles and improve the degassing effect.

The Air-Liquid method is a primary form of continuous processing outside the furnace. The bottom of the device is equipped with a breathable brick plug). Nitrogen passes through the breathable brick to form tiny bubbles, which rise in the melt. When the bubbles are in contact with the melt and move, they absorb the gas and impurities and bring them out of the surface to produce a purification effect. Although this method has the effect of removing slag, the effect is not very satisfactory.

SNIF is an external treatment device for aluminum melt furnace. Two gas rotating nozzles made of graphite are arranged in the two chambers, and the gas passes through the rotor of the nozzle to disperse fine bubbles. With the agitation of the rotor, the bubbles are evenly dispersed throughout the melt. This avoids the accumulation of bubbles caused by blowing in the gas in a single direction, and the continuous gas channel formed by the floating, shortens the contact time of the gas and the melt and affects the purification effect. The blowing gas is nitrogen and argon, and 2%~5% chlorine can be mixed in to improve the purification effect.

The Alpur method also uses rotating nozzles to disperse the refined gas in the melt in the form of fine bubble sprays. But different from the nozzle of SNIF, it agitates the melt into the nozzle at the same time to contact with the bubbles to make the purification effect.

The MINT method is a treatment device outside the melt furnace. The aluminum melt enters the cylindrical reaction chamber in a tangential manner from the entrance of the reactor, so that the melt rotates during its production. The lower part of the reactor is equipped with a gas nozzle to disperse and spray small bubbles, and the bubbles are evenly dispersed in the entire reactor by the action of the rotating melt, which produces a better purification effect. The melt flows out of the degassing unit and enters the ceramic foam filter, which can further remove non-metallic inclusions. The gas used for purification is argon, and a small amount of chlorine can also be added.