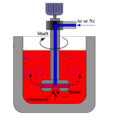

An aluminum online degassing system is used as a treatment system to promote the degassing and slag removal effects of molten aluminum alloys. This type of rotary degassing device has a nozzle that supplies inert gas at the center of the shaft of the rotor that rotates in a single direction. In the state that the rotating rotor is immersed in the molten aluminum alloy, argon, nitrogen or other inert gas is sprayed and supplied from the nozzle to the molten metal, while the rotating rotor is rotated at a speed of 200-650 rpm to make inclusions in the molten metal substances and the like float up to the surface of the molten metal along with the fine bubbles, so that degassing and slag removal are carried out together.

In recent years, AdTech has developed an aluminum online degassing system for foundry, it can provide inert gas to the center of the rotating rotor. By using this aluminum foundry degassing device, the degassing and deslagging effects can be effectively improved.

Degassing unit adopts new high silicon melting material manufacturing technology. The main components include a mechanical drive, box lid, rotor, and heater. AdTech degassing equipment can meet the production of aluminum products with high technical performance requirements. Aluminum degassing machine is between the furnace and the casting machine, the main function is removing hydrogen and other residues.

Place a molten aluminum degassing machine between the holding furnace and the casting machine. Blow the Nitrogen into the molten aluminum alloy, and the gas is shredded by the rotating graphite rotor in the degassing tank. Then a large number of dispersed bubbles are formed, so that the liquid aluminum alloy is in full contact with nitrogen in the treatment tank. According to the air pressure difference and the principle of surface adsorption, bubbles absorb hydrogen and oxidized slag. And then the bubbles rise to the surface of the melt to form scum. Then molten aluminum alloy flows from the outlet of the degassing unit to the casting machine. The liquid aluminum alloy continuously enters the degassing device, and nitrogen is continuously blown in. With such a purification process, the degassing machine can achieve the purpose of purifying the aluminum alloy.