Molten aluminum degassing system is an advanced molten aluminum purification equipment with built-in advanced heating elements.

According to the casting process requirements, the internal temperature is effectively controlled, and the on-line degassing device is used to remove gas and harmful impurities in aluminum and aluminum alloy melt.

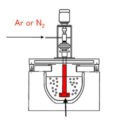

Aluminum and aluminum alloy melts are introduced into the purification equipment, and inert gas is injected into the melt through a rapidly rotating rotor, thus forming a large number of dispersed small bubbles.

In the process of floating in the solution, hydrogen and other inclusions are physically replaced by small bubbles on the surface of the solution, so that the aluminum and aluminum alloy solutions can achieve the effect of degassing and removing impurities.

The alloy elements of aluminum alloy solution can be more uniform by the rapid stirring of rotating nozzle in the solution.

The quality of casting can be improved effectively.

To ensure accurate positioning, two hydraulic cylinders are used as lifting devices to control the vertical upward movement of the graphite rotor and the heating system of the U-shaped silicon carbide heater.

It moves down and can rotate 90 ° horizontally. The hydraulic system is relatively stable and accurate positioning.

Process flow and principle of molten aluminum degassing system

Inert gas storage tank → online degassing device gas control cabinet → graphite rotor nozzle → processed aluminum alloy melt → purification and degassing treatment.

A degassing device is installed between the holding furnace and the casting machine, and the nitrogen blown into the aluminum alloy melt is chopped by the rotating graphite rotor in the degassing unit.

A large number of dispersed bubbles are formed, which makes the aluminum alloy liquid completely contact with nitrogen in the treatment tank. According to the principle of pressure difference and surface adsorption, the bubbles absorb the hydrogen in the melt and absorb the oxide slag, and then rise to the surface of the melt to form scum.

The aluminum alloy melt flows from the outlet of degassing device (located in the lower part of scum) to the casting machine, and the aluminum alloy liquid continuously enters the degassing device and continuously blows nitrogen. The purpose of purifying aluminum alloy liquid is achieved.