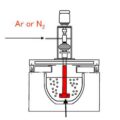

The purpose of degassing aluminium with nitrogen is to blow nitrogen into the molten aluminum to remove hydrogen. Nitrogen is ejected from the graphite nozzle of the rotary degasser and floats in the molten aluminum. In addition, degassing with nitrogen by aluminium degassing unit is also considered a very effective method for floating impurities.

Two main theoretical models have been proposed to explain the principle of degassing. The macro mode considers that the removal of each impurity is essentially similar. The microscopic mode, that is, according to the theory, the dissolved hydrogen diffuses into the gas injected into the molten aluminum due to the higher vapor pressure of hydrogen.

In theory, inclusions with a diameter of 10 microns are in contact with the bubbles and are adsorbed on the bubbles and float to the surface of the liquid.

The hydrogen partial pressure in the nitrogen bubbles just ejected from the graphite nozzle is zero. When nitrogen is floating, hydrogen diffuses from the aluminum liquid into the nitrogen bubbles under the driving force of the hydrogen pressure difference until the hydrogen partial pressure is reached. The pressure in the nitrogen bubble when the partial pressure of hydrogen in the aluminum liquid reaches equilibrium, the nitrogen phase stops, and then the nitrogen floats to the surface to be removed, thereby degassing.

Adtech Online Aluminium Degassing Unit Uses

- After the degassing box is heated, turn off the heating unit. When the heater temperature is close to the molten aluminum temperature, inert gas is introduced into the rotor and the molten aluminum is released into the box.

- Check the seal between the inlet/outlet and the sink.

- Check the cone located in the bottom thermal protection drain.

- Check the temperature of molten aluminum (minimum 720°C). Keep the height of the molten aluminum and the height of the bottom of the washing tank 3cm to observe the height of the molten aluminum entering the box.

- The operator should wear protective clothing to close the lid. When molten aluminum flows into the box, the slag on the surface can be skimmed off through the slag discharge port.

- Production starts when the temperature reaches 780°C. Close the slag outlet to conserve heat.

- Molten aluminum can be kept in the box at a set temperature during the holding period, without the need to handle molten aluminum.

- Inert gas is introduced into the rotor to prevent the aluminum melt from blocking the air outlet.

- After the molten aluminum has completely flowed into the tank, immediately turn on the heater and set the heat preservation parameters.

- Start the heating system, control the temperature of molten aluminum, monitor the gas flow, and change the speed of the rotor from the holding stage to the processing stage. At the same time, the flow of inert gas entering the rotor increases, and the flow of gas changes from the preservation phase to the treatment phase.

- The operator sets the heating temperature of molten aluminum to maintain stable degassing working conditions.

[…] the aluminum liquid passes through the degassing unit, the high-purity N2 online degassing method is used, and the alumina ceramic foam filter is used […]