Aluminum Foundry Fluxes are used to purify aluminum liquid. The Aluminum Foundry Fluxes should be stored in a dry place with high room temperature before use, such as next to the furnace, to prevent moisture.

Applying the covering flux in the furnace can reduce the melting consumption and prevent the aluminum liquid from absorbing gas from the furnace atmosphere, but the consumption of the covering flux is large (about 10% of the weight of the aluminum material), which increases the production cost. Small and medium-sized aluminum Processing plants are generally not used. The purification flux is usually used to scatter the powdered flux mixed in the proportion after the aluminum material is melted, and then stir the aluminum liquid with a long-handled tool to promote the slag to float. During the agitation process, part of the flux is added into the molten pool, and chemically reacts with the aluminum liquid to form a gaseous substance insoluble in aluminum, which plays the role of degassing and ash removal during the rise of bubbles.

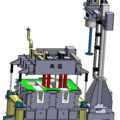

Dissolved hydrogen levels can be reduced by a number of methods, the most important of which is fluxing with dry, chemically pure nitrogen, argon, chlorine, and freon. Gas fluxing reduces the dissolved hydrogen content of molten aluminum by partial pressure diffusion. AdTech online degassing unit can degas by the inert gas, such as nitrogen, argon.

Inject an inert gas into the degassing box, the rotor rotates at high speed. And the large bubbles of inert gas are broken into very fine small bubbles, and they are evenly dispersed in the molten metal. By reducing the bubble diameter, the total surface area of these bubbles increases dramatically. This makes the surface of more inert bubbles come into contact with the hydrogen and impurities in the liquid metal. As the bubbles rise, the hydrogen and impurities are brought to the surface of the liquid for removal.

The flow rate of the inert gas is adjusted according to the volume of the metal liquid. The speed of the rotating rod and rotor can also be adjusted to produce bubbles of appropriate size to facilitate the diffusion of inert gas.